PART 393 - PARTS AND ACCESSORIES NECESSARY FOR SAFE OPERATION

Source:

33 FR 19735, Dec. 25, 1968, unless otherwise noted.

Subpart A - General

Source:

53 FR 49384, Dec. 7, 1988, unless otherwise noted.

§ 393.1 Scope of the rules in this part.

(a) The rules in this part establish minimum standards for commercial motor vehicles as defined in § 390.5 of this title. Only motor vehicles (as defined in § 390.5) and combinations of motor vehicles which meet the definition of a commercial motor vehicle are subject to the requirements of this part. All requirements that refer to motor vehicles with a GVWR below 4,536 kg (10,001 pounds) are applicable only when the motor vehicle or combination of motor vehicles meets the definition of a commercial motor vehicle.

(b)

(1) Every motor carrier and its employees must be knowledgeable of and comply with the requirements and specifications of this part.

(2) Every intermodal equipment provider and its employees or agents responsible for the inspection, repair, and maintenance of intermodal equipment interchanged to motor carriers must be knowledgeable of and comply with the applicable requirements and specifications of this part.

(c) No motor carrier may operate a commercial motor vehicle, or cause or permit such vehicle to be operated, unless it is equipped in accordance with the requirements and specifications of this part.

(d) No intermodal equipment provider may operate intermodal equipment, or cause or permit such equipment to be operated, unless it is equipped in accordance with the requirements and specifications of this part.

(e) The rules in this part do not apply to “pipeline welding trucks” as defined in 49 CFR 390.38(b).

[70 FR 48025, Aug. 15, 2005, as amended at 73 FR 76823, Dec. 17, 2008; 81 FR 47721, July 22, 2016]

§ 393.3 Additional equipment and accessories.

The use of additional equipment or accessories in a manner that decreases the safety of operation of a commercial motor vehicle in interstate commerce is prohibited. Nothing contained in this subchapter shall be construed to prohibit the use of additional equipment and accessories, not inconsistent with or prohibited by this subchapter, provided such equipment and accessories do not decrease the safety of operation of the motor vehicles on which they are used.

[78 FR 58484, Sept. 24, 2013]

§ 393.5 Definitions.

As used in this part, the following words and terms are construed to mean:

Aggregate working load limit. The summation of the working load limits or restraining capacity of all devices used to secure an article of cargo on a vehicle.

Agricultural commodity trailer. A trailer that is designed to transport bulk agricultural commodities in off-road harvesting sites and to a processing plant or storage location, as evidenced by skeletal construction that accommodates harvest containers, a maximum length of 28 feet, and an arrangement of air control lines and reservoirs that minimizes damage in field operations.

Air brake system. A system, including an air-over-hydraulic brake subsystem, that uses air as a medium for transmitting pressure or force from the driver control to the service brake, but does not include a system that uses compressed air or vacuum only to assist the driver in applying muscular force to hydraulic or mechanical components.

Air-over-hydraulic brake subsystem. A subsystem of the air brake system that uses compressed air to transmit a force from the driver control to a hydraulic brake system to actuate the service brakes.

Anchor point. Part of the structure, fitting or attachment on a vehicle or article of cargo to which a tiedown is attached.

Antilock Brake System or ABS means a portion of a service brake system that automatically controls the degree of rotational wheel slip during braking by:

(1) Sensing the rate of angular rotation of the wheels;

(2) Transmitting signals regarding the rate of wheel angular rotation to one or more controlling devices which interpret those signals and generate responsive controlling output signals; and

(3) Transmitting those controlling signals to one or more modulators which adjust brake actuating forces in response to those signals.

Article of cargo. A unit of cargo, other than a liquid, gas, or aggregate that lacks physical structure (e.g., grain, gravel, etc.) including articles grouped together so that they can be handled as a single unit or unitized by wrapping, strapping, banding or edge protection device(s).

Auxiliary driving lamp. A lighting device mounted to provide illumination forward of the vehicle which supplements the upper beam of a standard headlighting system. It is not intended for use alone or with the lower beam of a standard headlamp system.

Bell pipe concrete. Pipe whose flanged end is of larger diameter than its barrel.

Blocking. A structure, device or another substantial article placed against or around an article of cargo to prevent horizontal movement of the article of cargo.

Boat trailer. A trailer designed with cradle-type mountings to transport a boat and configured to permit launching of the boat from the rear of the trailer.

Bracing. A structure, device, or another substantial article placed against an article of cargo to prevent it from tipping, that may also prevent it from shifting.

Brake. An energy conversion mechanism used to stop, or hold a vehicle stationary.

Brake power assist unit. A device installed in a hydraulic brake system that reduces the operator effort required to actuate the system, but which if inoperative does not prevent the operator from braking the vehicle by a continued application of muscular force on the service brake control.

Brake power unit. A device installed in a brake system that provides the energy required to actuate the brakes, either directly or indirectly through an auxiliary device, with the operator action consisting only of modulating the energy application level.

Brake tubing/hose. Metallic brake tubing, nonmetallic brake tubing and brake hose are conduits or lines used in a brake system to transmit or contain the medium (fluid or vacuum) used to apply the motor vehicle's brakes.

Chassis. The load-supporting frame of a commercial motor vehicle, exclusive of any appurtenances which might be added to accommodate cargo.

Clearance Lamps. Lamps that provide light to the front or rear, mounted on the permanent structure of the vehicle, such that they indicate the overall width of the vehicle.

Container chassis trailer. A semitrailer of skeleton construction limited to a bottom frame, one or more axles, specially built and fitted with locking devices for the transport of intermodal cargo containers, so that when the chassis and container are assembled, the units serve the same function as an over the road trailer.

Converter dolly. A motor vehicle consisting of a chassis equipped with one or more axles, a fifth wheel and/or equivalent mechanism, and drawbar, the attachment of which converts a semitrailer to a full trailer.

Crib-type log trailer means a trailer equipped with stakes, bunks, a front-end structure, and a rear structure to restrain logs. The stakes prevent movement of the logs from side to side on the vehicle while the front-end and rear structures prevent movement of the logs from front to back on the vehicle.

Curb weight. The weight of a motor vehicle with standard equipment, maximum capacity of fuel, oil, and coolant; and, if so equipped, air conditioning and additional weight of optional engine. Curb weight does not include the driver.

Dunnage. All loose materials used to support and protect cargo.

Dunnage bag. An inflatable bag intended to fill otherwise empty space between articles of cargo, or between articles of cargo and the wall of the vehicle.

Edge protector. A device placed on the exposed edge of an article to distribute tiedown forces over a larger area of cargo than the tiedown itself, to protect the tie-down and/or cargo from damage, and to allow the tiedown to slide freely when being tensioned.

Electric brake system. A system that uses electric current to actuate the service brake.

Emergency brake. A mechanism designed to stop a motor vehicle after a failure of the service brake system.

Emergency brake system. A mechanism designed to stop a vehicle after a single failure occurs in the service brake system of a part designed to contain compressed air or brake fluid or vacuum (except failure of a common valve, manifold brake fluid housing or brake chamber housing).

Fifth wheel. A device mounted on a truck tractor or similar towing vehicle (e.g., converter dolly) which interfaces with and couples to the upper coupler assembly of a semitrailer.

Frame vehicle. A vehicle with skeletal structure fitted with one or more bunk units for transporting logs. A bunk unit consists of U-shaped front and rear bunks that together cradle logs. The bunks are welded, gusseted or otherwise firmly fastened to the vehicle's main beams, and are an integral part of the vehicle.

Friction mat. A device placed between the deck of a vehicle and article of cargo, or between articles of cargo, intended to provide greater friction than exists naturally between these surfaces.

Front fog lamp. A lighting device whose beam provides downward illumination forward of the vehicle and close to the ground, and is to be used only under conditions of rain, snow, dust, smoke or fog. A pair of fog lamps may be used alone, with parking, tail, side, marker, clearance and identification lamps, or with a lower beam headlamp at the driver's discretion in accordance with state and local use law.

Fuel tank fitting. Any removable device affixed to an opening in the fuel tank with the exception of the filler cap.

g. The acceleration due to gravity, 32.2 ft/sec2 (9.81 m/sec2).

Grommet. A device that serves as a support and protection to that which passes through it.

Hazard warning signal. Lamps that flash simultaneously to the front and rear, on both the right and left sides of a commercial motor vehicle, to indicate to an approaching driver the presence of a vehicular hazard.

Head lamps. Lamps used to provide general illumination ahead of a motor vehicle.

Heater. Any device or assembly of devices or appliances used to heat the interior of any motor vehicle. This includes a catalytic heater which must meet the requirements of § 177.834(l)(2) of this title when Class 3 (flammable liquid) or Division 2.1 (flammable gas) is transported.

Heavy hauler trailer. A trailer which has one or more of the following characteristics, but which is not a container chassis trailer:

(1) Its brake lines are designed to adapt to separation or extension of the vehicle frame; or

(2) Its body consists only of a platform whose primary cargo-carrying surface is not more than 1,016 mm (40 inches) above the ground in an unloaded condition, except that it may include sides that are designed to be easily removable and a permanent “front-end structure” as that term is used in § 393.106 of this title.

Hook-lift container. A specialized container, primarily used to contain and transport materials in the waste, recycling, construction/demolition and scrap industries, which is used in conjunction with specialized vehicles, in which the container is loaded and unloaded onto a tilt frame body by an articulating hook-arm.

Hydraulic brake system. A system that uses hydraulic fluid as a medium for transmitting force from a service brake control to the service brake, and that may incorporate a brake power assist unit, or a brake power unit.

Identification lamps. Lamps used to identify certain types of commercial motor vehicles.

Integral securement system. A system on certain roll-on/roll-off containers and hook-lift containers and their related transport vehicles in which compatible front and rear hold down devices are mated to provide securement of the complete vehicle and its articles of cargo.

Lamp. A device used to produce artificial light.

Length of a manufactured home. The largest exterior length in the traveling mode, including any projections which contain interior space. Length does not include bay windows, roof projections, overhangs, or eaves under which there is no interior space, nor does it include drawbars, couplings or hitches.

License plate lamp. A lamp used to illuminate the license plate on the rear of a motor vehicle.

Longwood. All logs that are not shortwood, i.e., are over 4.9 m (16 feet) long. Such logs are usually described as long logs or treelength.

Low chassis vehicle.

(1) A trailer or semitrailer manufactured on or after January 26, 1998, having a chassis which extends behind the rearmost point of the rearmost tires and which has a lower rear surface that meets the guard width, height, and rear surface requirements of § 571.224 in effect on the date of manufacture, or a subsequent edition.

(2) A motor vehicle, not described by paragraph (1) of this definition, having a chassis which extends behind the rearmost point of the rearmost tires and which has a lower rear surface that meets the guard configuration requirements of § 393.86(b)(1).

Major tread groove is the space between two adjacent tread ribs or lugs on a tire that contains a tread wear indicator or wear bar. (In most cases, the locations of tread wear indicators are designated on the upper sidewall/shoulder of the tire on original tread tires.)

Manufactured home means a structure, transportable in one or more sections, which in the traveling mode, is eight body feet or more in width or forty body feet or more in length, or, when erected on site, is three hundred twenty or more square feet, and which is built on a permanent chassis and designed to be used as a dwelling with or without a permanent foundation when connected to the required utilities, and includes the plumbing, heating, air-conditioning, and electrical systems contained therein. Calculations used to determine the number of square feet in a structure will be based on the structure's exterior dimensions measured at the largest horizontal projections when erected on site. These dimensions will include all expandable rooms, cabinets, and other projections containing interior space, but do not include bay windows. This term includes all structures which meet the above requirements except the size requirements and with respect to which the manufacturer voluntarily files a certification pursuant to 24 CFR 3282.13 and complies with the standards set forth in 24 CFR part 3280.

Metal coil means an article of cargo comprised of elements, mixtures, compounds, or alloys commonly known as metal, metal foil, metal leaf, forged metal, stamped metal, metal wire, metal rod, or metal chain that are packaged as a roll, coil, spool, wind, or wrap, including plastic or rubber coated electrical wire and communications cable

Multi-piece windshield. A windshield consisting of two or more windshield glazing surface areas.

Parking brake system. A mechanism designed to prevent the movement of a stationary motor vehicle.

Play. Any free movement of components.

Pulpwood trailer. A trailer or semitrailer that is designed exclusively for harvesting logs or pulpwood and constructed with a skeletal frame with no means for attachment of a solid bed, body, or container.

Rail vehicle. A vehicle whose skeletal structure is fitted with stakes at the front and rear to contain logs loaded crosswise.

Rear extremity. The rearmost point on a motor vehicle that falls above a horizontal plane located 560 mm (22 inches) above the ground and below a horizontal plane located 1,900 mm (75 inches) above the ground when the motor vehicle is stopped on level ground; unloaded; its fuel tanks are full; the tires (and air suspension, if so equipped) are inflated in accordance with the manufacturer's recommendations; and the motor vehicle's cargo doors, tailgate, or other permanent structures are positioned as they normally are when the vehicle is in motion. Nonstructural protrusions such as taillamps, rubber bumpers, hinges and latches are excluded from the determination of the rearmost point.

Reflective material. A material conforming to Federal Specification L-S-300, “Sheeting and Tape, Reflective; Non-exposed Lens, Adhesive Backing,” (September 7, 1965) meeting the performance standard in either Table 1 or Table 1A of SAE Standard J594f, “Reflex Reflectors” (January, 1977).

Reflex reflector. A device which is used on a vehicle to give an indication to an approaching driver by reflected lighted from the lamps on the approaching vehicle.

Saddle-mount. A device, designed and constructed as to be readily demountable, used in driveaway-towaway operations to perform the functions of a conventional fifth wheel:

(1) Upper-half. Upper-half of a “saddle-mount” means that part of the device which is securely attached to the towed vehicle and maintains a fixed position relative thereto, but does not include the “king-pin;”

(2) Lower-half. Lower-half of a “saddle-mount” means that part of the device which is securely attached to the towing vehicle and maintains a fixed position relative thereto but does not include the “king-pin;” and

(3) King-pin. King-pin means that device which is used to connect the “upper-half” to the “lower-half” in such manner as to permit relative movement in a horizontal plane between the towed and towing vehicles.

Service brake system. A primary brake system used for slowing and stopping a vehicle.

Shoring bar. A device placed transversely between the walls of a vehicle and cargo to prevent cargo from tipping or shifting.

Shortwood. All logs typically up to 4.9 m (16 feet) long. Such logs are often described as cut-up logs, cut-to-length logs, bolts or pulpwood. Shortwood may be loaded lengthwise or crosswise, though that loaded crosswise is usually no more than 2.6 m (102 inches) long.

Sided vehicle. A vehicle whose cargo compartment is enclosed on all four sides by walls of sufficient strength to contain articles of cargo, where the walls may include latched openings for loading and unloading, and includes vans, dump bodies, and a sided intermodal container carried by a vehicle.

Side extremity. The outermost point on a side of the motor vehicle that is above a horizontal plane located 560 mm (22 inches) above the ground, below a horizontal plane located 1,900 mm (75 inches) above the ground, and between a transverse vertical plane tangent to the rear extremity of the vehicle and a transverse vertical plane located 305 mm (12 inches) forward of that plane when the vehicle is unloaded; its fuel tanks are full; and the tires (and air suspension, if so equipped) are inflated in accordance with the manufacturer's recommendations. Non-structural protrusions such as taillights, hinges and latches are excluded from the determination of the outermost point.

Side marker lamp (Intermediate). A lamp mounted on the side, on the permanent structure of the motor vehicle that provides light to the side to indicate the approximate middle of the vehicle, when the motor vehicle is 9.14 meters (30 feet) or more in length.

Side marker lamps. Lamps mounted on the side, on the permanent structure of the motor vehicle as near as practicable to the front and rear of the vehicle, that provide light to the side to indicate the overall length of the motor vehicle.

Special purpose vehicle.

(1) A trailer or semitrailer manufactured on or after January 26, 1998, having work-performing equipment that, while the motor vehicle is in transit, resides in or moves through the area that could be occupied by the horizontal member of the rear impact guard, as defined by the guard width, height and rear surface requirements of § 571.224 (paragraphs S5.1.1 through S5.1.3), in effect on the date of manufacture, or a subsequent edition.

(2) A motor vehicle, not described by paragraph (1) of this definition, having work-performing equipment that, while the motor vehicle is in transit, resides in or moves through the area that could be occupied by the horizontal member of the rear impact guard, as defined by the guard width, height and rear surface requirements of § 393.86(b)(1).

Split service brake system. A brake system consisting of two or more subsystems actuated by a single control designed so that a leakage-type failure of a pressure component in a single subsystem (except structural failure of a housing that is common to two or more subsystems) shall not impair the operation of any other subsystem.

Steering wheel lash. The condition in which the steering wheel may be turned through some part of a revolution without associated movement of the front wheels.

Stop lamps. Lamps shown to the rear of a motor vehicle to indicate that the service brake system is engaged.

Surge brake. A self-contained, permanently closed hydraulic brake system for trailers that relies on inertial forces, developed in response to the braking action of the towing vehicle, applied to a hydraulic device mounted on or connected to the tongue of the trailer, to slow down or stop the towed vehicle.

Tail lamps. Lamps used to designate the rear of a motor vehicle.

Tiedown. A combination of securing devices which forms an assembly that attaches articles of cargo to, or restrains articles of cargo on, a vehicle or trailer, and is attached to anchor point(s).

Tow bar. A strut or column-like device temporarily attached between the rear of a towing vehicle and the front of the vehicle being towed.

Tractor-pole trailer. A combination vehicle that carries logs lengthwise so that they form the body of the vehicle. The logs are supported by a bunk located on the rear of the tractor, and another bunk on the skeletal trailer. The tractor bunk may rotate about a vertical axis, and the trailer may have a fixed, scoping, or cabled reach, or other mechanical freedom, to allow it to turn.

Trailer kingpin. A pin (with a flange on its lower end) which extends vertically from the front of the underside of a semitrailer and which locks into a fifth wheel.

Turn signals. Lamps used to indicate a change in direction by emitting a flashing light on the side of a motor vehicle towards which a turn will be made.

Upper coupler assembly. A structure consisting of an upper coupler plate, king-pin and supporting framework which interfaces with and couples to a fifth wheel.

Upper coupler plate. A plate structure through which the king-pin neck and collar extend. The bottom surface of the plate contacts the fifth wheel when coupled.

Vacuum brake system. A system that uses a vacuum and atmospheric pressure for transmitting a force from the driver control to the service brake, not including a system that uses vacuum only to assist the driver in applying muscular force to hydraulic or mechanical components.

Vehicle safety technology. Vehicle safety technology includes a fleet-related incident management system, performance or behavior management system, speed management system, lane departure warning system, forward collision warning or mitigation system, active cruise control system, and transponder.

Void filler. Material used to fill a space between articles of cargo and the structure of the vehicle that has sufficient strength to prevent movement of the articles of cargo.

Well. The depression formed between two cylindrical articles of cargo when they are laid with their eyes horizontal and parallel against each other.

Wheels back vehicle.

(1) A trailer or semitrailer manufactured on or after January 26, 1998, whose rearmost axle is permanently fixed and is located such that the rearmost surface of the tires (of the size recommended by the vehicle manufacturer for the rear axle) is not more than 305 mm (12 inches) forward of the transverse vertical plane tangent to the rear extremity of the vehicle.

(2) A motor vehicle, not described by paragraph (1) of this definition, whose rearmost axle is permanently fixed and is located such that the rearmost surface of the tires (of the size recommended by the vehicle manufacturer for the rear axle) is not more than 610 mm (24 inches) forward of the transverse vertical plane tangent to the rear extremity of the vehicle.

Width of a manufactured home. The largest exterior width in the traveling mode, including any projections which contain interior space. Width does not include bay windows, roof projections, overhangs, or eaves under which there is no interior space.

Windshield. The principal forward facing glazed surface provided for forward vision in operating a motor vehicle.

Working load limit (WLL). The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

[53 FR 49384, Dec. 7, 1988, as amended at 63 FR 8339, Feb. 18, 1998; 63 FR 24465, May 4, 1998; 64 FR 47707, Sept. 1, 1999; 67 FR 61224, Sept. 27, 2002; 68 FR 56208, Sept. 30, 2003; 70 FR 48026, Aug. 15, 2005; 71 FR 35832, June 22, 2006; 72 FR 9870, Mar. 6, 2007; 81 FR 47731, July 22, 2016; 81 FR 65574, Sept. 23, 2016]

§ 393.7 Matter incorporated by reference.

(a) Incorporation by reference. Part 393 includes references to certain matter or materials, as listed in paragraph (b) of this section. The text of the materials is not included in the regulations contained in part 393. The materials are hereby made a part of the regulations in part 393. The Director of the Federal Register has approved the materials incorporated by reference in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. For materials subject to change, only the specific version approved by the Director of the Federal Register and specified in the regulation are incorporated. Material is incorporated as it exists on the date of the approval and a notice of any change in these materials will be published in the Federal Register.

(b) Matter or materials referenced in part 393. The matter or materials listed in this paragraph are incorporated by reference in the corresponding sections noted.

(1) Auxiliary Upper Beam Lamps, Society of Automotive Engineers (SAE) J581, July 2004, incorporation by reference approved for § 393.24(b).

(2) Front Fog Lamp, SAE J583, August 2004, incorporation by reference approved for § 393.24(b).

(3) Stop Lamps for Use on Motor Vehicles Less Than 2032 mm in Overall Width, SAE J586, March 2000, incorporation by reference approved for § 393.25(c).

(4) Stop Lamps and Front- and Rear-Turn Signal Lamps for Use on Motor Vehicles 2032 mm or more in Overall Width, SAE J2261, January 2002, incorporated by reference approved for § 393.25 (c).

(5) Tail Lamps (Rear Position Lamps) for Use on Motor Vehicles Less Than 2032 mm in Overall Width, SAE J585, March 2000, incorporation by reference approved for § 393.25(c).

(6) Tail Lamps (Rear Position Lamps) for Use on Vehicles 2032 mm or More in Overall Width, SAE J2040, March 2002, incorporation by reference approved for § 393.25(c).

(7) Turn Signal Lamps for Use on Motor Vehicles Less Than 2032 mm in Overall Width, SAE J588, March 2000, incorporation by reference approved for § 393.25(c).

(8) Sidemarker Lamps for Use on Road Vehicles Less Than 2032 mm in Overall Width, SAE J592, August 2000, incorporation by reference approved for § 393.25(c).

(9) Directional Flashing Optical Warning Devices for Authorized Emergency, Maintenance, and Service Vehicles, SAE J595, January 2005, incorporation by reference approved for § 393.25(e).

(10) Optical Warning Devices for Authorized Emergency, Maintenance, and Service Vehicles, SAE J845, May 1997, incorporation by reference approved for § 393.25(e).

(11) Gaseous Discharge Warning Lamp for Authorized Emergency, Maintenance, and Service Vehicles, SAE J1318, May 1998, incorporation by reference approved for § 393.25(e).

(12) Reflex Reflectors, SAE J594, December 2003, incorporation by reference approved for § 393.26(c).

(13) Standard Specification for Retroreflective Sheeting for Traffic Control, American Society of Testing and Materials, ASTM D 4956-04, 2004, incorporation by reference approved for § 393.26(c).

(14) Automobile, Truck, Truck-Tractor, Trailer, and Motor Coach Wiring, SAE J1292, October 1981, incorporated by reference approved for § 393.28.

(15) Highway Emergency Signals, Fourth Edition, Underwriters Laboratories, Inc., UL No. 912, July 30, 1979 (with an amendment dated November 9, 1981), incorporation by reference approved for § 393.95(j).

(16) American National Standard for Safety Glazing Materials for Glazing Motor Vehicles and Motor Vehicle Equipment Operating on Land Highways-Safety Standard, SAE Z26.1-1996, August 1997, incorporation by reference approved for § 393.62(d).

(17) Specification for Sound Level Meters, American National Standards Institute, S1.4-1983, incorporation by reference approved for § 393.94(c).

(18) Standard Specification for Strapping, Flat Steel and Seals, American Society for Testing and Materials (ASTM), D3953-97, February 1998, incorporation by reference approved for § 393.104(e).

(19) Welded Steel Chain Specifications, National Association of Chain Manufacturers, September 28, 2005, incorporation by reference approved for § 393.104(e).

(20) Recommended Standard Specification for Synthetic Web Tiedowns, Web Sling and Tiedown Association, WSTDA-T1, 1998, incorporation by reference approved for § 393.104(e).

(21) Wire Rope Users Manual, 2nd Edition, Wire Rope Technical Board November 1985, incorporation by reference approved for § 393.104(e).

(22) Cordage Institute rope standards approved for incorporation into § 393.104(e):

(i) PETRS-2, Polyester Fiber Rope, 3-Strand and 8-Strand Constructions, January 1993;

(ii) PPRS-2, Polypropylene Fiber Rope, 3-Strand and 8-Strand Constructions, August 1992;

(iii) CRS-1, Polyester/Polypropylene Composite Rope Specifications, Three-Strand and Eight-Strand Standard Construction, May 1979;

(iv) NRS-1, Nylon Rope Specifications, Three-Strand and Eight-Strand Standard Construction, May 1979; and

(v) C-1, Double Braided Nylon Rope Specifications DBN, January 1984.

(c) Availability. The materials incorporated by reference are available as follows:

(1) Standards of the Underwriters Laboratories, Inc. Information and copies may be obtained by writing to: Underwriters Laboratories, Inc., 333 Pfingsten Road, Northbrook, Illinois 60062.

(2) Specifications of the American Society for Testing and Materials. Information and copies may be obtained by writing to: American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, Pennsylvania 19428-2959.

(3) Specifications of the National Association of Chain Manufacturers. Information and copies may be obtained by writing to: National Association of Chain Manufacturers, P.O. Box 22681, Lehigh Valley, Pennsylvania 18002-2681.

(4) Specifications of the Web Sling and Tiedown Association. Information and copies may be obtained by writing to: Web Sling and Tiedown Association, Inc., 5024-R Campbell Boulevard, Baltimore, Maryland 21236-5974.

(5) Manuals of the Wire Rope Technical Board. Information and copies may be obtained by writing to: Wire Rope Technical Committee, P.O. Box 849, Stevensville, Maryland 21666.

(6) Standards of the Cordage Institute. Information and copies may be obtained by writing to: Cordage Institute, 350 Lincoln Street, # 115, Hingham, Massachusetts 02043.

(7) Standards of the Society of Automotive Engineers (SAE). Information and copies may be obtained by writing to: Society of Automotive Engineers, Inc., 400 Commonwealth Drive, Warrendale, Pennsylvania 15096.

(8) Standards of the American National Standards Institute (ANSI). Information and copies may be obtained by writing to: American National Standards Institute, 25 West 43rd Street, New York, New York 10036.

(9) [Reserved].

(10) All of the materials incorporated by reference are available for inspection at:

(i) Federal Motor Carrier Safety Administration, Office of Bus and Truck Standards and Operations (MC-PS), 1200 New Jersey Ave., SE., Washington, DC 20590-0001; and

(ii) The National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call 202-741-6030, or go to: http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html.

[67 FR 61225, Sept. 27, 2002, as amended at 70 FR 48027, Aug. 15, 2005; 71 FR 35832, June 22, 2006; 72 FR 55703, Oct. 1, 2007; 77 FR 46638, Aug. 6, 2012; 80 FR 59075, Oct. 1, 2015]

Subpart B - Lamps, Reflective Devices, and Electrical Wiring

§ 393.9 Lamps operable, prohibition of obstructions of lamps and reflectors.

(a) All lamps required by this subpart shall be capable of being operated at all times. This paragraph shall not be construed to require that any auxiliary or additional lamp be capable of operating at all times.

(b) Lamps and reflective devices/material required by this subpart must not be obscured by the tailboard, or by any part of the load, or its covering by dirt, or other added vehicle or work equipment, or otherwise. Exception: The conspicuity treatments on the front end protection devices may be obscured by part of the load being transported.

[70 FR 48027, Aug. 15, 2005]

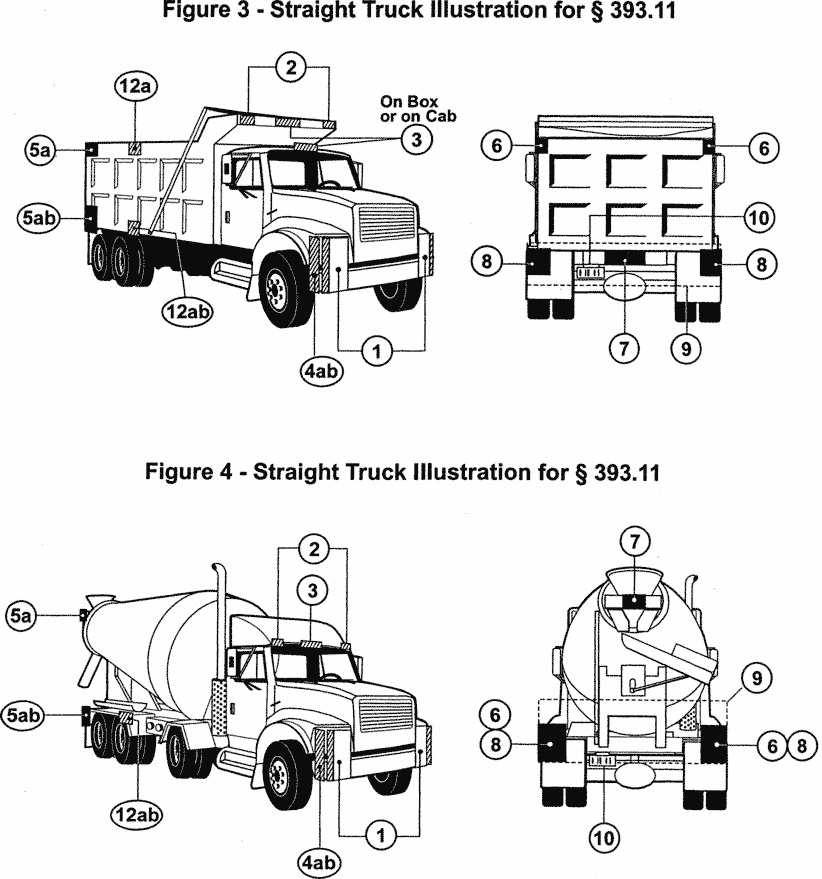

§ 393.11 Lamps and reflective devices.

(a)

(1) Lamps and reflex reflectors. Table 1 specifies the requirements for lamps, reflective devices and associated equipment by the type of commercial motor vehicle. The diagrams in this section illustrate the position of the lamps, reflective devices and associated equipment specified in Table 1. All commercial motor vehicles manufactured on or after December 25, 1968, must, at a minimum, meet the applicable requirements of 49 CFR 571.108 (FMVSS No. 108) in effect at the time of manufacture of the vehicle. Commercial motor vehicles manufactured before December 25, 1968, must, at a minimum, meet the requirements of subpart B of part 393 in effect at the time of manufacture.

(2) Exceptions: Pole trailers and trailer converter dollies must meet the part 393 requirements for lamps, reflective devices and electrical equipment in effect at the time of manufacture. Trailers which are equipped with conspicuity material which meets the requirements of § 393.11(b) are not required to be equipped with the reflex reflectors listed in Table 1 if—

(i) The conspicuity material is placed at the locations where reflex reflectors are required by Table 1; and

(ii) The conspicuity material when installed on the motor vehicle meets the visibility requirements for the reflex reflectors.

(b) Conspicuity Systems. Each trailer of 2,032 mm (80 inches) or more overall width, and with a GVWR over 4,536 kg (10,000 pounds), manufactured on or after December 1, 1993, except pole trailers and trailers designed exclusively for living or office use, shall be equipped with either retroreflective sheeting that meets the requirements of FMVSS No. 108 (S5.7.1), reflex reflectors that meet the requirements FMVSS No. 108 (S5.7.2), or a combination of retroreflective sheeting and reflex reflectors that meet the requirements of FMVSS No. 108 (S5.7.3). The conspicuity system shall be installed and located as specified in FMVSS No. 108 [S5.7.1.4 (for retroreflective sheeting), S5.7.2.2 (for reflex reflectors), S5.7.3 (for a combination of sheeting and reflectors)] and have certification and markings as required by S5.7.1.5 (for retroreflective tape) and S5.7.2.3 (for reflex reflectors).

(c) Prohibition on the use of amber stop lamps and tail lamps. No commercial motor vehicle may be equipped with an amber stop lamp, a tail lamp, or other lamp which is optically combined with an amber stop lamp or tail lamp.

Table 1 of § 393.11—Required Lamps and Reflectors on Commercial Motor Vehicles

| Item on the vehicle | Quantity | Color | Location | Position | Height above the road surface in millimeters (mm) (with English units in parenthesis) measured from the center of the lamp at curb weight | Vehicles for which the devices are required |

|---|---|---|---|---|---|---|

| Headlamps | 2 | White | Front | On the front at the same height, with an equal number at each side of the vertical center line as far apart as practicable | Not less than 559 mm (22 inches) nor more than 1,372 mm (54 inches) | A, B, C |

| Turn signal (front). See footnotes #2 and 12 | 2 | Amber | At or near the front | One on each side of the vertical centerline at the same height and as far apart as practicable | Not less than 381 mm (15 inches) nor more than 2,108 mm (83 inches) | A, B, C |

| Identification lamps (front). See footnote #1 | 3 | Amber | Front | As close as practicable to the top of the vehicle, at the same height, and as close as practicable to the vertical centerline of the vehicle (or the vertical centerline of the cab where different from the centerline of the vehicle) with lamp centers spaced not less than 152 mm (6 inches) or more than 305 mm (12 inches) apart. Alternatively, the front lamps may be located as close as practicable to the top of the cab | All three on the same level as close as practicable to the top of the motor vehicle | B, C |

| Tail lamps. See footnotes #5 and 11 | 2 | Red | Rear | One lamp on each side of the vertical centerline at the same height and as far apart as practicable | Both on the same level between 381 mm (15 inches) and 1,829 mm (72 inches) | A, B, C, D, E, F, G, H |

| Stop lamps. See footnotes #5 and 13 | 2 | Red | Rear | One lamp on each side of the vertical centerline at the same height and as far apart as practicable | Both on the same level between 381 mm (15 inches) and 1,829 mm (72 inches) | A, B, C, D, E, F, G |

| Clearance lamps. See footnotes #8, 9, 10, 15 & 17 | 2 | Amber | One on each side of the front of the vehicle | One on each side of the vertical centerline to indicate overall width | Both on the same level as high as practicable | B, C, D, G, H |

| 2 | Red | One on each side of the rear of the vehicle | One on each side of the vertical centerline to indicate overall width | Both on the same level as high as practicable | B, D, G, H | |

| Reflex reflector, intermediate (side) | 2 | Amber | One on each side | At or near the midpoint between the front and rear side marker lamps, if the length of the vehicle is more than 9,144 mm (30 feet) | Between 381 mm (15inches) and 1,524 (60 inches) | A, B, D, F, G |

| Reflex reflector (rear). See footnotes #5, 6, and 8 | 2 | Red | Rear | One on each side of the vertical centerline, as far apart as practicable and at the same height | Both on the same level, between 381 mm (15 inches) and 1,524 mm (60 inches) | A, B, C, D, E, F, G |

| Reflex reflector (rear side). | 2 | Red | One on each side (rear) | As far to the rear as practicable | Both on the same level, between 381 mm (15 inches) and 1,524 mm (60 inches) | A, B, D, F, G |

| Reflex reflector (front side). See footnote #16 | 2 | Amber | One on each side (front) | As far to the front as practicable | Between 381 mm (15 inches) and 1,524 mm (60 inches) | A, B, C, D, F, G |

| License plate lamp (rear). See footnote #11 | 1 | White | At rear license plate to illuminate the plate from the top or sides | No requirements | A, B, C, D, F, G | |

| Side marker lamp (front). See footnote #16 | 2 | Amber | One on each side | As far to the front as practicable | Not less than 381 mm (15 inches) | A, B, C, D, F |

| Side marker lamp intermediate | 2 | Amber | One on each side | At or near the midpoint between the front and rear side marker lamps, if the length of the vehicle is more than 9,144 mm (30 feet) | Not less tan 381 mm (15 inches) | A, B, D, F, G |

| Side marker lamp (rear). See footnotes #4 and 8 | 2 | Red | One on each side | As far to the rear as practicable | Not less than 381 mm (15 inches), and on the rear of trailers not more than 1,524 mm (60 inches) | A, B, D, F, G |

| Turn signal (rear). See footnotes #5 and 12 | 2 | Amber or red | Rear | One lamp on each side of the vertical centerline as far apart as practicable | Both on the same level, between 381 mm (15 inches) and 2,108 mm (83 inches) | A, B, C, D, E, F, G |

| Identification lamp (rear). See footnotes #3, 7, and 15 | 3 | Red | Rear | One as close as practicable to the vertical centerline. One on each side with lamp centers spaced not less than 152 mm (6 inches) or more than 305 mm (12 inches) apart | All three on the same level as close as practicable to the top of the vehicle | B, D, G |

| Vehicular hazard warning signal flasher lamps. See footnotes #5 and 12 | 2 | Amber | Front | One lamp on each side of the vertical centerline, as far apart as practicable | Both on the same level, between 381 mm (15 inches) and 2,108 mm (83 inches) | A, B, C |

| 2 | Amber or red | Rear | One lamp on each side of the vertical centerline, as far apart as practicable | Both on the same level, between 381 mm (15 inches) and 2,108 mm (83 inches) | A, B, C, D, E, F, G | |

| Backup lamp. See footnote #14 | 1 or 2 | White | Rear | Rear | No requirement | A, B, C |

| Parking lamp | 2 | Amber or white | Front | One lamp on each side of the vertical centerline, as far apart as practicable | Both on the same level, between 381 mm (15 inches) and 2,108 mm (83 inches) | A |

[70 FR 48027, Aug. 15, 2005, as amended at 72 FR 32014, June 11, 2007; 72 FR 33562, June 18, 2007; 78 FR 58484, Sept. 24, 2013; 81 FR 47731, July 22, 2016; 81 FR 60634, Sept. 2, 2016]

§ 393.13 Retroreflective sheeting and reflex reflectors, requirements for semitrailers and trailers manufactured before December 1, 1993.

(a) Applicability. All trailers and semitrailers manufactured prior to December 1, 1993, which have an overall width of 2,032 mm (80 inches) or more and a gross vehicle weight rating of 4,536 kg (10,001 pounds) or more, except trailers that are manufactured exclusively for use as offices or dwellings, pole trailers (as defined in § 390.5 of this subchapter), and trailers transported in a driveaway-towaway operation, must be equipped with retroreflective sheeting or an array of reflex reflectors that meet the requirements of this section. Motor carriers operating trailers, other than container chassis (as defined in § 393.5), have until June 1, 2001, to comply with the requirements of this section. Motor carriers operating container chassis have until December 1, 2001, to comply with the requirements of this section.

(b) Retroreflective sheeting and reflex reflectors. Motor carriers are encouraged to retrofit their trailers with a conspicuity system that meets all of the requirements applicable to trailers manufactured on or after December 1, 1993, including the use of retroreflective sheeting or reflex reflectors in a red and white pattern (see Federal Motor Vehicle Safety Standard No. 108 (49 CFR 571.108), S5.7, Conspicuity systems). Motor carriers which do not retrofit their trailers to meet the requirements of FMVSS No. 108, for example by using an alternative color pattern, must comply with the remainder of this paragraph and with paragraph (c) or (d) of this section. Retroreflective sheeting or reflex reflectors in colors or color combinations other than red and white may be used on the sides or lower rear area of the semitrailer or trailer until June 1, 2009. The alternate color or color combination must be uniform along the sides and lower rear area of the trailer. The retroreflective sheeting or reflex reflectors on the upper rear area of the trailer must be white and conform to the requirements of FMVSS No. 108 (S5.7). Red retroreflective sheeting or reflex reflectors shall not be used along the sides of the trailer unless it is used as part of a red and white pattern. Retroreflective sheeting shall have a width of at least 50 mm (2 inches).

(c) Locations for retroreflective sheeting —

(1) Sides. Retroreflective sheeting shall be applied to each side of the trailer or semitrailer. Each strip of retroreflective sheeting shall be positioned as horizontally as practicable, beginning and ending as close to the front and rear as practicable. The strip need not be continuous but the sum of the length of all of the segments shall be at least half of the length of the trailer and the spaces between the segments of the strip shall be distributed as evenly as practicable. The centerline for each strip of retroreflective sheeting shall be between 375 mm (15 inches) and 1,525 mm (60 inches) above the road surface when measured with the trailer empty or unladen, or as close as practicable to this area. If necessary to clear rivet heads or other similar obstructions, 50 mm (2 inches) wide retroreflective sheeting may be separated into two 25 mm (1 inch) wide strips of the same length and color, separated by a space of not more than 25 mm (1 inch).

(2) Lower rear area. The rear of each trailer and semitrailer must be equipped with retroreflective sheeting. Each strip of retroreflective sheeting shall be positioned as horizontally as practicable, extending across the full width of the trailer, beginning and ending as close to the extreme edges as practicable. The centerline for each of the strips of retroreflective sheeting shall be between 375 mm (15 inches) and 1,525 mm (60 inches) above the road surface when measured with the trailer empty or unladen, or as close as practicable to this area.

(3) Upper rear area. Two pairs of white strips of retroreflective sheeting, each pair consisting of strips 300 mm (12 inches) long, must be positioned horizontally and vertically on the right and left upper corners of the rear of the body of each trailer and semitrailer, as close as practicable to the top of the trailer and as far apart as practicable. If the perimeter of the body, as viewed from the rear, is not square or rectangular, the strips may be applied along the perimeter, as close as practicable to the uppermost and outermost areas of the rear of the body on the left and right sides.

(d) Locations for reflex reflectors —

(1) Sides. Reflex reflectors shall be applied to each side of the trailer or semitrailer. Each array of reflex reflectors shall be positioned as horizontally as practicable, beginning and ending as close to the front and rear as practicable. The array need not be continuous but the sum of the length of all of the array segments shall be at least half of the length of the trailer and the spaces between the segments of the strip shall be distributed as evenly as practicable. The centerline for each array of reflex reflectors shall be between 375 mm (15 inches) and 1,525 mm (60 inches) above the road surface when measured with the trailer empty or unladen, or as close as practicable to this area. The center of each reflector shall not be more than 100 mm (4 inches) from the center of each adjacent reflector in the segment of the array. If reflex reflectors are arranged in an alternating color pattern, the length of reflectors of the first color shall be as close as practicable to the length of the reflectors of the second color.

(2) Lower rear area. The rear of each trailer and semitrailer must be equipped with reflex reflectors. Each array of reflex reflectors shall be positioned as horizontally as practicable, extending across the full width of the trailer, beginning and ending as close to the extreme edges as practicable. The centerline for each array of reflex reflectors shall be between 375 mm (15 inches) and 1,525 mm (60 inches) above the road surface when measured with the trailer empty or unladen, or as close as practicable to this area. The center of each reflector shall not be more than 100 mm (4 inches) from the center of each adjacent reflector in the segment of the array.

(3) Upper rear area. Two pairs of white reflex reflector arrays, each pair at least 300 mm (12 inches) long, must be positioned horizontally and vertically on the right and left upper corners of the rear of the body of each trailer and semitrailer, as close as practicable to the top of the trailer and as far apart as practicable. If the perimeter of the body, as viewed from the rear, is not square or rectangular, the arrays may be applied along the perimeter, as close as practicable to the uppermost and outermost areas of the rear of the body on the left and right sides. The center of each reflector shall not be more than 100 mm (4 inches) from the center of each adjacent reflector in the segment of the array.

[64 FR 15605, Mar. 31, 1999, as amended at 66 FR 30339, June 6, 2001]

§ 393.17 Lamps and reflectors—combinations in driveaway-towaway operation.

A combination of motor vehicles engaged in driveaway-towaway operation must be equipped with operative lamps and reflectors conforming to the rules in this section.

(a) The towing vehicle must be equipped as follows:

(1) On the front, there must be at least two headlamps, an equal number at each side, two turn signals, one at each side, and two clearance lamps, one at each side.

(2) On each side, there must be at least one side-marker lamp, located near the front of the vehicle.

(3) On the rear, there must be at least two tail lamps, one at each side, and two stop lamps, one at each side.

(b) Except as provided in paragraph (c) of this section, the rearmost towed vehicle of the combination (including the towed vehicles of a tow-bar combination, the towed vehicle of a single saddle-mount combination, and the rearmost towed vehicle of a double or triple saddle-mount combination) or, in the case of a vehicle full-mounted on a saddle-mount vehicle, either the full-mounted vehicle or the rearmost saddle-mounted vehicle must be equipped as follows:

(1) On each side, there must be at least one side-marker lamp, located near the rear of the vehicle.

(2) On the rear, there must be at least two tail lamps, two stop lamps, two turn signals, two clearance lamps, and two reflectors, one of each type at each side. In addition, if any vehicle in the combination is 80 inches or more in overall width, there must be three identification lamps on the rear.

(c) If the towed vehicle in a combination is a mobile structure trailer, it must be equipped in accordance with the following lighting devices. For the purposes of this part, mobile structure trailer means a trailer that has a roof and walls, is at least 10 feet wide, and can be used off road for dwelling or commercial purposes.

(1) When the vehicle is operated in accordance with the terms of a special permit prohibiting operation during the times when lighted lamps are required, it must have on the rear—

(i) Two stop lamps, one on each side of the vertical centerline, at the same height, and as far apart as practicable;

(ii) Two tail lamps, one on each side of the vertical centerline, at the same height, and as far apart as practicable;

(iii) Two red reflex reflectors, one on each side of the vertical centerline, at the same height, and as far apart as practicable; and

(iv) Two turn signal lamps, one on each side of the vertical centerline, at the same height, and as far apart as practicable.

(2) At all other times, the vehicle must be equipped as specified in paragraph (b) of this section.

(d) An intermediate towed vehicle in a combination consisting of more than two vehicles (including the first saddle-mounted vehicle of a double saddle-mount combination and the first and second saddle-mount vehicles of a triple saddle-mount combination) must have one side-marker lamp on each side, located near the rear of the vehicle.

[40 FR 36126, Aug. 19, 1975, as amended at 47 FR 47837, Oct. 28, 1982; 70 FR 48044, Aug. 15, 2005; 77 FR 59828, Oct. 1, 2012; 80 FR 59075, Oct. 1, 2015]

§ 393.19 Hazard warning signals.

The hazard warning signal operating unit on each commercial motor vehicle shall operate independently of the ignition or equivalent switch, and when activated, cause all turn signals required by § 393.11 to flash simultaneously.

[70 FR 48046, Aug. 15, 2005]

§ 393.20 [Reserved]

§ 393.22 Combination of lighting devices and reflectors.

(a) Permitted combinations. Except as provided in paragraph (b) of this section, two or more lighting devices and reflectors (whether or not required by the rules in this part) may be combined optically if—

(1) Each required lighting device and reflector conforms to the applicable rules in this part; and

(2) Neither the mounting nor the use of a nonrequired lighting device or reflector impairs the effectiveness of a required lighting device or reflector or causes that device or reflector to be inconsistent with the applicable rules in this part.

(b) Prohibited combinations.

(1) A turn signal lamp must not be combined optically with either a head lamp or other lighting device or combination of lighting devices that produces a greater intensity of light than the turn signal lamp.

(2) A turn signal lamp must not be combined optically with a stop lamp unless the stop lamp function is always deactivated when the turn signal function is activated.

(3) A clearance lamp must not be combined optically with a tail lamp or identification lamp.

[39 FR 26908, July 24, 1974]

§ 393.23 Power supply for lamps.

All required lamps must be powered by the electrical system of the motor vehicle with the exception of battery powered lamps used on projecting loads.

[70 FR 48046, Aug. 15, 2005]

§ 393.24 Requirements for head lamps, auxiliary driving lamps and front fog lamps.

(a) Headlamps. Every bus, truck and truck tractor shall be equipped with headlamps as required by § 393.11(a). The headlamps shall provide an upper and lower beam distribution of light, selectable at the driver's will and be steady-burning. The headlamps shall be marked in accordance with FMVSS No. 108. Auxiliary driving lamps and/or front fog lamps may not be used to satisfy the requirements of this paragraph.

(b) Auxiliary driving lamps and front fog lamps. Commercial motor vehicles may be equipped with auxiliary driving lamps and/or front fog lamps for use in conjunction with, but not in lieu of the required headlamps. Auxiliary driving lamps shall meet SAE Standard J581 Auxiliary Upper Beam Lamps, July 2004, and front fog lamps shall meet SAE Standard J583 Front Fog Lamp, August 2004. (See § 393.7 for information on the incorporation by reference and availability of these documents.)

(c) Mounting. Headlamps shall be mounted and aimable in accordance with FMVSS No. 108. Auxiliary driving lamps and front fog lamps shall be mounted so that the beams are aimable and the mounting shall prevent the aim of the lighting device from being disturbed while the vehicle is operating on public roads.

(d) Aiming. Headlamps, auxiliary driving lamps and front fog lamps shall be aimed to meet the aiming specifications in FMVSS No. 108 (49 CFR 571.108), SAE J581, and SAE J583, respectively.

[70 FR 48046, Aug. 15, 2005]

§ 393.25 Requirements for lamps other than head lamps.

(a) Mounting. All lamps shall be securely mounted on a rigid part of the vehicle. Temporary lamps must be securely mounted to the load and are not required to be mounted to a permanent part of the vehicle.

(b) Visibility. Each lamp shall be located so that it meets the visibility requirements specified by FMVSS No. 108 in effect at the time of manufacture of the vehicle. Vehicles which were not subject to FMVSS No. 108 at the time of manufacture shall have each lamp located so that it meets the visibility requirements specified in the SAE standards listed in paragraph (c) of this section. If motor vehicle equipment (e.g., mirrors, snow plows, wrecker booms, backhoes, and winches) prevents compliance with this paragraph by any required lamp, an auxiliary lamp or device meeting the requirements of this paragraph shall be provided. This shall not be construed to apply to lamps on one unit which are obscured by another unit of a combination of vehicles.

(c) Specifications. All required lamps (except marker lamps on projecting loads, lamps which are temporarily attached to vehicles transported in driveaway-towaway operations, and lamps on converter dollies and pole trailers) on vehicles manufactured on or after December 25, 1968, shall, at a minimum, meet the applicable requirements of FMVSS No. 108 in effect on the date of manufacture of the vehicle. Marker lamps on projecting loads, all lamps which are temporarily attached to vehicles transported in driveaway-towaway operations, and all lamps on converter dollies and pole trailers must meet the following applicable SAE standards: J586—Stop Lamps for Use on Motor Vehicles Less Than 2032 mm in Overall Width, March 2000; J2261 Stop Lamps and Front- and Rear-Turn Signal Lamps for Use on Motor Vehicles 2032 mm or More in Overall Width, January 2002; J585—Tail Lamps (Rear Position Lamps) for Use on Motor Vehicles Less Than 2032 mm in Overall Width, March 2000; J588—Turn Signal Lamps for Use on Motor Vehicles Less Than 2032 mm in Overall Width, March 2000; J2040—Tail Lamps (Rear Position Lamps) for Use on Vehicles 2032 mm or More in Overall Width, March 2002; J592—Sidemarker Lamps for Use on Road Vehicles Less Than 2032 mm in Overall Width, August 2000. (See § 393.7 for information on the incorporation by reference and availability of these documents.)

(d) (Reserved)

(e) Lamps to be steady-burning. All exterior lamps (both required lamps and any additional lamps) shall be steady-burning with the exception of turn signal lamps; hazard warning signal lamps; school bus warning lamps; amber warning lamps or flashing warning lamps on tow trucks and commercial motor vehicles transporting oversized loads; and warning lamps on emergency and service vehicles authorized by State or local authorities. Lamps combined into the same shell or housing with a turn signal are not required to be steady burning while the turn signal is in use. Amber warning lamps must meet SAE J845—Optical Warning Devices for Authorized Emergency, Maintenance and Service Vehicles, May 1997. Amber flashing warning lamps must meet SAE J595—Directional Flashing Optical Warning Devices for Authorized Emergency, Maintenance and Service Vehicles, January 2005. Amber gaseous discharge warning lamps must meet SAE J1318 Gaseous Discharge Warning Lamp for Authorized Emergency, Maintenance, and Service Vehicles, May 1998. (See § 393.7(b) for information on the incorporation by reference and availability of these documents.)

(f) Stop lamp operation. The stop lamps on each vehicle shall be activated upon application of the service brakes. The stop lamps are not required to be activated when the emergency feature of the trailer brakes is used or when the stop lamp is optically combined with the turn signal and the turn signal is in use.

[70 FR 48047, Aug. 15, 2005]

§ 393.26 Requirements for reflectors.

(a) Mounting. Reflex reflectors shall be mounted at the locations required by § 393.11. In the case of motor vehicles so constructed that requirement for a 381 mm (15-inch) minimum height above the road surface is not practical, the reflectors shall be mounted as close as practicable to the required mounting height range. All permanent reflex reflectors shall be securely mounted on a rigid part of the vehicle. Temporary reflectors on projecting loads must be securely mounted to the load and are not required to be permanently mounted to a part of the vehicle. Temporary reflex reflectors on vehicles transported in driveaway-towaway operations must be firmly attached.

(b) Specifications. All required reflex reflectors (except reflex reflectors on projecting loads, vehicles transported in a driveaway-towaway operation, converter dollies and pole trailers) on vehicles manufactured on or after December 25, 1968, shall meet the applicable requirements of FMVSS No. 108 in effect on the date of manufacture of the vehicle. Reflex reflectors on projecting loads, vehicles transported in a driveaway-towaway operation, and all reflex reflectors on converter dollies and pole trailers must conform to SAE J594—Reflex Reflectors, December 2003.

(c) Substitute material for side reflex reflectors. Reflective material conforming to ASTM D 4956-04, Standard Specification for Retroreflective Sheeting for Traffic Control, may be used in lieu of reflex reflectors if the material as used on the vehicle, meets the performance standards in either Table I of SAE J594 or Table IA of SAE J594—Reflex Reflectors, December 2003. (See § 393.7(b) for information on the incorporation by reference and availability of these documents.)

(d) Use of additional retroreflective surfaces. Additional retroreflective surfaces may be used in conjunction with, but not in lieu of the reflex reflectors required in subpart B of part 393, and the substitute material for side reflex reflectors allowed by paragraph (c) of this section, provided:

(1) Designs do not resemble traffic control signs, lights, or devices, except that straight edge striping resembling a barricade pattern may be used.

(2) Designs do not tend to distort the length and/or width of the motor vehicle.

(3) Such surfaces shall be at least 3 inches from any required lamp or reflector unless of the same color as such lamp or reflector.

(4) No red color shall be used on the front of any motor vehicle, except for display of markings or placards required by § 177.823 of this title.

(5) Retroreflective license plates required by State or local authorities may be used.

[33 FR 19735, Dec. 25, 1968, as amended at 35 FR 3167, Feb. 19, 1970; 53 FR 49397, Dec. 7, 1988; 70 FR 48047, Aug. 15, 2005]

§ 393.27 [Reserved]

§ 393.28 Wiring systems.

Electrical wiring shall be installed and maintained to conform to SAE J1292—Automobile, Truck, Truck-Tractor, Trailer, and Motor Coach Wiring, October 1981, except the jumper cable plug and receptacle need not conform to SAE J560. The reference to SAE J1292 shall not be construed to require circuit protection on trailers. (See § 393.7(b) for information on the incorporation by reference and availability of this document.)

[70 FR 48047, Aug. 15, 2005]

§ 393.29 [Reserved]

§ 393.30 Battery installation.

Every storage battery on every vehicle, unless located in the engine compartment, shall be covered by a fixed part of the motor vehicle or protected by a removable cover or enclosure. Removable covers or enclosures shall be substantial and shall be securely latched or fastened. The storage battery compartment and adjacent metal parts which might corrode by reason of battery leakage shall be painted or coated with an acid-resisting paint or coating and shall have openings to provide ample battery ventilation and drainage. Wherever the cable to the starting motor passes through a metal compartment, the cable shall be protected against grounding by an acid and waterproof insulating bushing. Wherever a battery and a fuel tank are both placed under the driver's seat, they shall be partitioned from each other, and each compartment shall be provided with an independent cover, ventilation, and drainage.

§§ 393.31-393.33 [Reserved]

Subpart C - Brakes

§ 393.40 Required brake systems.

(a) Each commercial motor vehicle must have brakes adequate to stop and hold the vehicle or combination of motor vehicles. Each commercial motor vehicle must meet the applicable service, parking, and emergency brake system requirements provided in this section.

(b) Service brakes —

(1) Hydraulic brake systems. Motor vehicles equipped with hydraulic brake systems and manufactured on or after September 2, 1983, must, at a minimum, have a service brake system that meets the requirements of FMVSS No. 105 in effect on the date of manufacture. Motor vehicles which were not subject to FMVSS No. 105 on the date of manufacture must have a service brake system that meets the applicable requirements of §§ 393.42, 393.48, 393.49, 393.51, and 393.52 of this subpart.

(2) Air brake systems. Buses, trucks and truck-tractors equipped with air brake systems and manufactured on or after March 1, 1975, and trailers manufactured on or after January 1, 1975, must, at a minimum, have a service brake system that meets the requirements of FMVSS No. 121 in effect on the date of manufacture. Motor vehicles which were not subject to FMVSS No. 121 on the date of manufacture must have a service brake system that meets the applicable requirements of §§ 393.42, 393.48, 393.49, 393.51, and 393.52 of this subpart.

(3) Vacuum brake systems. Motor vehicles equipped with vacuum brake systems must have a service brake system that meets the applicable requirements of §§ 393.42, 393.48, 393.49, 393.51, and 393.52 of this subpart.

(4) Electric brake systems. Motor vehicles equipped with electric brake systems must have a service brake system that meets the applicable requirements of §§ 393.42, 393.48, 393.49 and 393.52 of this subpart.

(5) Surge brake systems. Motor vehicles equipped with surge brake systems must have a service brake system that meets the applicable requirements of §§ 393.42, 393.48, 393.49, and 393.52 of this subpart.

(c) Parking brakes. Each commercial motor vehicle must be equipped with a parking brake system that meets the applicable requirements of § 393.41.

(d) Emergency brakes—partial failure of service brakes —

(1) Hydraulic brake systems. Motor vehicles manufactured on or after September 2, 1983, and equipped with a split service brake system must, at a minimum, meet the partial failure requirements of FMVSS No. 105 in effect on the date of manufacture.

(2) Air brake systems. Buses, trucks and truck tractors manufactured on or after March 1, 1975, and trailers manufactured on or after January 1, 1975, must be equipped with an emergency brake system which, at a minumum, meets the requirements of FMVSS No. 121 in effect on the date of manufacture.

(3) Vehicles not subject to FMVSS Nos. 105 and 121 on the date of manufacture. Buses, trucks and truck tractors not subject to FMVSS Nos. 105 or 121 on the date of manufacture must meet the requirements of § 393.40(e). Trailers not subject to FMVSS No. 121 at the time of manufacture must meet the requirements of § 393.43.

(e) Emergency brakes, vehicles manufactured on or after July 1, 1973.

(1) A bus, truck, truck tractor, or a combination of motor vehicles manufactured on or after July 1, 1973, and not covered under paragraphs (d)(1) or (d)(2) of this section, must have an emergency brake system which consists of emergency features of the service brake system or an emergency system separate from the service brake system. The emergency brake system must meet the applicable requirements of §§ 393.43 and 393.52.

(2) A control by which the driver applies the emergency brake system must be located so that the driver can operate it from the normal seating position while restrained by any seat belts with which the vehicle is equipped. The emergency brake control may be combined with either the service brake control or the parking brake control. However, all three controls may not be combined.

(f) Interconnected systems.

(1) If the brake systems required by § 393.40(a) are interconnected in any way, they must be designed, constructed, and maintained so that in the event of a failure of any part of the operating mechanism of one or more of the systems (except the service brake actuation pedal or valve), the motor vehicle will have operative brakes and, for vehicles manufactured on or after July 1, 1973, be capable of meeting the requirements of § 393.52(b).

(2) A motor vehicle to which the requirements of FMVSS No. 105 (S5.1.2), dealing with partial failure of the service brake, applied at the time of manufacture meets the requirements of § 393.40(f)(1) if the motor vehicle is maintained in conformity with FMVSS No. 105 and the motor vehicle is capable of meeting the requirements of § 393.52(b), except in the case of a structural failure of the brake master cylinder body.

(3) A bus is considered to meet the requirements of § 393.40(f)(1) if it meets the requirements of § 393.44 and § 393.52(b).

[70 FR 48048, Aug. 15, 2005, as amended at 72 FR 9870, Mar. 6, 2007]

§ 393.41 Parking brake system.

(a) Hydraulic-braked vehicles manufactured on or after September 2, 1983. Each truck and bus (other than a school bus) with a GVWR of 4,536 kg (10,000 pounds) or less which is subject to this part and school buses with a GVWR greater than 4,536 kg (10,000 pounds) shall be equipped with a parking brake system as required by FMVSS No. 571.105 (S5.2) in effect at the time of manufacture. The parking brake shall be capable of holding the vehicle or combination of vehicles stationary under any condition of loading in which it is found on a public road (free of ice and snow). Hydraulic-braked vehicles which were not subject to the parking brake requirements of FMVSS No. 571.105 (S5.2) must be equipped with a parking brake system that meets the requirements of paragraph (c) of this section.

(b) Air-braked power units manufactured on or after March 1, 1975, and air-braked trailers manufactured on or after January 1, 1975. Each air-braked bus, truck and truck tractor manufactured on and after March 1, 1975, and each air-braked trailer except an agricultural commodity trailer, converter dolly, heavy hauler trailer or pulpwood trailer, shall be equipped with a parking brake system as required by FMVSS No. 121 (S5.6) in effect at the time of manufacture. The parking brake shall be capable of holding the vehicle or combination of vehicles stationary under any condition of loading in which it is found on a public road (free of ice and snow). An agricultural commodity trailer, heavy hauler or pulpwood trailer shall carry sufficient chocking blocks to prevent movement when parked.

(c) Vehicles not subject to FMVSS Nos. 105 and 121 on the date of manufacture.

(1) Each singly driven motor vehicle not subject to parking brake requirements of FMVSS Nos. 105 or 121 at the time of manufacturer, and every combination of motor vehicles must be equipped with a parking brake system adequate to hold the vehicle or combination on any grade on which it is operated, under any condition of loading in which it is found on a public road (free of ice and snow).

(2) The parking brake system shall, at all times, be capable of being applied by either the driver's muscular effort or by spring action. If other energy is used to apply the parking brake, there must be an accumulation of that energy isolated from any common source and used exclusively for the operation of the parking brake.

Exception: This paragraph shall not be applicable to air-applied, mechanically-held parking brake systems which meet the parking brake requirements of FMVSS No. 121 (S5.6).

(3) The parking brake system shall be held in the applied position by energy other than fluid pressure, air pressure, or electric energy. The parking brake system shall not be capable of being released unless adequate energy is available to immediately reapply the parking brake with the required effectiveness.

[70 FR 48048, Aug. 15, 2005]

§ 393.42 Brakes required on all wheels.

(a) Every commercial motor vehicle shall be equipped with brakes acting on all wheels. This requirement also applies to certain motor vehicles being towed in a driveaway-towaway operation, as follows:

(1) Any motor vehicle towed by means of a tow-bar when another motor vehicle is full-mounted on the towed vehicle; and

(2) Any saddlemount configuration with a fullmount.

(b) Exception.

(1) Trucks or truck tractors having three or more axles and manufactured before July 25, 1980, are not required to have brakes on the front wheels. However, these vehicles must meet the requirements of § 393.52.

(2) Motor vehicles being towed in a driveaway-towaway operation (including the last truck of triple saddle-mount combinations (see § 393.71(a)(3)) are not required to have operative brakes provided the combination of vehicles meets the requirements of § 393.52.

(3) Any semitrailer or pole trailer (laden or unladen) with a gross weight of 1,361 kg (3,000 pounds) or less which is subject to this part is not required to be equipped with brakes if the axle weight of the towed vehicle does not exceed 40 percent of the sum of the axle weights of the towing vehicle.

(4) Any full trailer or four-wheel pole trailer (laden or unladen) with a gross weight of 1,361 kg (3,000 pounds) or less which is subject to this part is not required to be equipped with brakes if the sum of the axle weights of the towed vehicle does not exceed 40 percent of the sum of the axle weights of the towing vehicle.

(5) Brakes are not required on the steering axle of a three-axle dolly which is steered by a co-driver.

(6) Loaded housemoving dollies, specialized trailers and dollies used to transport industrial furnaces, reactors, and similar motor vehicles are not required to be equipped with brakes, provided the speed at which the combination of vehicles will be operated does not exceed 32 km/hour (20 mph) and brakes on the combination of vehicles are capable of stopping the combination within 12.2 meters (40 feet) from the speed at which the vehicle is being operated or 32 km/hour (20 mph), whichever is less.

[52 FR 2803, Jan. 27, 1987, as amended at 53 FR 49398, Dec. 7, 1988; 54 FR 48617, Nov. 24, 1989; 59 FR 25574, May 17, 1994; 61 FR 1843, Jan. 24, 1996; 70 FR 48049, Aug. 15, 2005; 76 FR 56321, Sept. 13, 2011]

§ 393.43 Breakaway and emergency braking.

(a) Towing vehicle protection system. Every motor vehicle, if used to tow a trailer equipped with brakes, shall be equipped with a means for providing that in the case of a breakaway of the trailer, the service brakes on the towing vehicle will be capable of stopping the towing vehicle. For air braked towing units, the tractor protection valve or similar device shall operate automatically when the air pressure on the towing vehicle is between 138 kPa and 310 kPa (20 psi and 45 psi).

(b) Emergency brake requirements, air brakes. Every truck or truck tractor equipped with air brakes, when used for towing other vehicles equipped with air brakes, shall be equipped with two means of activating the emergency features of the trailer brakes. One of these means shall operate automatically in the event of reduction of the towing vehicle air supply to a fixed pressure which shall not be lower than 20 pounds per square inch nor higher than 45 pounds per square inch. The other means shall be a manually controlled device readily operable by a person seated in the driving seat. Its emergency position or method of operation shall be clearly indicated. In no instance may the manual means be so arranged as to permit its use to prevent operation of the automatic means. The automatic and manual means required by this section may be, but are not required to be, separate.

(c) Emergency brake requirements, vacuum brakes. Every truck tractor and truck when used for towing other vehicles equipped with vacuum brakes, shall have, in addition to the single control required by § 393.49 to operate all brakes of the combination, a second manual control device which can be used to operate the brakes on the towed vehicles in emergencies. Such second control shall be independent of brake air, hydraulic, and other pressure, and independent of other controls, unless the braking system be so arranged that failure of the pressure on which the second control depends will cause the towed vehicle brakes to be applied automatically. The second control is not required by this rule to provide modulated or graduated braking.

(d) Breakaway braking requirements for trailers. Every trailer required to be equipped with brakes shall have brakes which apply automatically and immediately upon breakaway from the towing vehicle. With the exception of trailers having three or more axles, all brakes with which the trailer is required to be equipped must be applied upon breakaway from the towing vehicle. The brakes must remain in the applied position for at least 15 minutes.

(e) Emergency valves. Air brake systems installed on towed vehicles shall be so designed, by the use of “no-bleed-back” relay emergency valves or equivalent devices, that the supply reservoir used to provide air for brakes shall be safeguarded against backflow of air to the towing vehicle upon reduction of the towing vehicle air pressure.

(f) Exception. The requirements of paragraphs (b), (c) and (d) of this section shall not be applicable to commercial motor vehicles being transported in driveaway-towaway operations.

[53 FR 49384, Dec. 7, 1988, as amended at 70 FR 48050, Aug. 15, 2005]

§ 393.44 Front brake lines, protection.

On every bus, if equipped with air brakes, the braking system shall be so constructed that in the event any brake line to any of the front wheels is broken, the driver can apply the brakes on the rear wheels despite such breakage. The means used to apply the brakes may be located forward of the driver's seat as long as it can be operated manually by the driver when the driver is properly restrained by any seat belt assembly provided for use. Every bus shall meet this requirement or comply with the regulations in effect at the time of its manufacture.

[53 FR 49400, Dec. 7, 1988]

§ 393.45 Brake tubing and hoses; hose assemblies and end fittings.

(a) General construction requirements for tubing and hoses, assemblies, and end fittings. All brake tubing and hoses, brake hose assemblies, and brake hose end fittings must meet the applicable requirements of FMVSS No. 106 (49 CFR 571.106).

(b) Brake tubing and hose installation. Brake tubing and hose must—

(1) Be long and flexible enough to accommodate without damage all normal motions of the parts to which it is attached;

(2) Be secured against chaffing, kinking, or other mechanical damage; and

(3) Be installed in a manner that prevents it from contacting the vehicle's exhaust system or any other source of high temperatures.

(c) Nonmetallic brake tubing. Coiled nonmetallic brake tubing may be used for connections between towed and towing motor vehicles or between the frame of a towed vehicle and the unsprung subframe of an adjustable axle of the motor vehicle if—