PART 173 - SHIPPERS - GENERAL REQUIREMENTS FOR SHIPMENTS AND PACKAGINGS

Subpart A - General

§ 173.1 Purpose and scope.

(a) This part includes:

(1) Definitions of hazardous materials for transportation purposes;

(2) Requirements to be observed in preparing hazardous materials for shipment by air, highway, rail, or water, or any combination thereof; and

(3) Inspection, testing, and retesting responsibilities for persons who retest, recondition, maintain, repair and rebuild containers used or intended for use in the transportation of hazardous materials.

(b) A shipment of hazardous materials that is not prepared in accordance with this subchapter may not be offered for transportation by air, highway, rail, or water. It is the responsibility of each hazmat employer subject to the requirements of this subchapter to ensure that each hazmat employee is trained in accordance with the requirements prescribed in this subchapter. It is the duty of each person who offers hazardous materials for transportation to instruct each of his officers, agents, and employees having any responsibility for preparing hazardous materials for shipment as to applicable regulations in this subchapter.

(c) In general, the Hazardous Materials Regulations (HMR) contained in this subchapter are based on the UN Recommendations and are consistent with international regulations issued by the International Civil Aviation Organization (ICAO Technical Instructions) and the International Maritime Organization (IMDG Code). However, the HMR are not consistent in all respects with the UN Recommendations, the ICAO Technical Instructions or the IMDG Code, and compliance with the HMR will not guarantee acceptance by regulatory bodies outside of the United States.

[Amdt. 173-94, 41 FR 16062, Apr. 15, 1976, as amended by Amdt. 173-100, 41 FR 40476, Sept. 20, 1976; Amdt. 173-161, 48 FR 2655, Jan. 20, 1983; Amdt. 173-224, 55 FR 52606, Dec. 21, 1990; Amdt. 173-231, 57 FR 20953, May 15, 1992; 64 FR 10776, Mar. 5, 1999; 68 FR 61941, Oct. 30, 2003]

§ 173.2 Hazardous materials classes and index to hazard class definitions.

The hazard class of a hazardous material is indicated either by its class (or division) number, its class name, or by the letters “ORM-D”. The following table lists class numbers, division numbers, class or division names and those sections of this subchapter which contain definitions for classifying hazardous materials, including forbidden materials.

| Class No. | Division No. (if any) | Name of class or division | 49 CFR reference for definitions |

|---|---|---|---|

| None | Forbidden materials | 173.21 | |

| None | Forbidden explosives | 173.54 | |

| 1 | 1.1 | Explosives (with a mass explosion hazard) | 173.50 |

| 1 | 1.2 | Explosives (with a projection hazard) | 173.50 |

| 1 | 1.3 | Explosives (with predominately a fire hazard) | 173.50 |

| 1 | 1.4 | Explosives (with no significant blast hazard) | 173.50 |

| 1 | 1.5 | Very insensitive explosives; blasting agents | 173.50 |

| 1 | 1.6 | Extremely insensitive detonating substances | 173.50 |

| 2 | 2.1 | Flammable gas | 173.115 |

| 2 | 2.2 | Non-flammable compressed gas | 173.115 |

| 2 | 2.3 | Poisonous gas | 173.115 |

| 3 | Flammable and combustible liquid | 173.120 | |

| 4 | 4.1 | Flammable solid | 173.124 |

| 4 | 4.2 | Spontaneously combustible material | 173.124 |

| 4 | 4.3 | Dangerous when wet material | 173.124 |

| 5 | 5.1 | Oxidizer | 173.127 |

| 5 | 5.2 | Organic peroxide | 173.128 |

| 6 | 6.1 | Poisonous materials | 173.132 |

| 6 | 6.2 | Infectious substance (Etiologic agent) | 173.134 |

| 7 | Radioactive material | 173.403 | |

| 8 | Corrosive material | 173.136 | |

| 9 | Miscellaneous hazardous material | 173.140 | |

| None | Other regulated material: ORM-D | 173.144 |

[Amdt. 173-224, 55 FR 52606, Dec. 21, 1990, as amended at 57 FR 45460, Oct. 1, 1992; Amdt. 173-234, 58 FR 51531, Oct. 1, 1993]

§ 173.2a Classification of a material having more than one hazard.

(a) Classification of a material having more than one hazard. Except as provided in paragraph (c) of this section, a material not specifically listed in the § 172.101 Table or assigned to an entry of articles containing hazardous materials (UN3537 to UN3548) that meets the definition of more than one hazard class or division as defined in this part, shall be classed according to the highest applicable hazard class of the following hazard classes, which are listed in descending order of hazard:

(1) Class 7 (radioactive materials, other than limited quantities; and shipments of UN 3507, Uranium hexafluoride, radioactive material, excepted package)

(2) Division 2.3 (poisonous gases).

(3) Division 2.1 (flammable gases).

(4) Division 2.2 (nonflammable gases).

(5) Division 6.1 (poisonous liquids), Packing Group I, poisonous-by-inhalation only.

(6) A material that meets the definition of a pyrophoric material in § 173.124(b)(1) of this subchapter (Division 4.2).

(7) A material that meets the definition of a self-reactive material in § 173.124(a)(2) of this subchapter (Division 4.1).

(8) Class 3 (flammable liquids), Class 8 (corrosive materials), Division 4.1 (flammable solids), Division 4.2 (spontaneously combustible materials), Division 4.3 (dangerous when wet materials), Division 5.1 (oxidizers) or Division 6.1 (poisonous liquids or solids other than Packing Group I, poisonous-by-inhalation). The hazard class and packing group for a material meeting more than one of these hazards shall be determined using the precedence table in paragraph (b) of this section.

(9) Combustible liquids.

(10) Class 9 (miscellaneous hazardous materials).

(b) Precedence of hazard table for Classes 3 and 8 and Divisions 4.1, 4.2, 4.3, 5.1 and 6.1. The following table ranks those materials that meet the definition of Classes 3 and 8 and Divisions 4.1, 4.2, 4.3, 5.1 and 6.1:

Precedence of Hazard Table

[ Hazard class or division and packing group ]

| 4.2 | 4.3 | 5.1 I1 | 5.1 II1 | 5.1 III1 | 6.1, I dermal | 6.1, I oral | 6.1 II | 6.1 III | 8, I liquid | 8, I solid | 8, II liquid | 8, II solid | 8, III liquid | 8, III solid | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 I2 | 4.3 | 3 | 3 | 3 | 3 | 3 | (3) | 3 | (3) | 3 | (3) | ||||

| 3 II2 | 4.3 | 3 | 3 | 3 | 3 | 8 | (3) | 3 | (3) | 3 | (3) | ||||

| 3 III2 | 4.3 | 6.1 | 6.1 | 6.1 | 34 | 8 | (3) | 8 | (3) | 3 | (3) | ||||

| 4.1 II2 | 4.2 | 4.3 | 5.1 | 4.1 | 4.1 | 6.1 | 6.1 | 4.1 | 4.1 | (3) | 8 | (3) | 4.1 | (3) | 4.1 |

| 4.1 III2 | 4.2 | 4.3 | 5.1 | 4.1 | 4.1 | 6.1 | 6.1 | 6.1 | 4.1 | (3) | 8 | (3) | 8 | (3) | 4.1 |

| 4.2 II | 4.3 | 5.1 | 4.2 | 4.2 | 6.1 | 6.1 | 4.2 | 4.2 | 8 | 8 | 4.2 | 4.2 | 4.2 | 4.2 | |

| 4.2 III | 4.3 | 5.1 | 5.1 | 4.2 | 6.1 | 6.1 | 6.1 | 4.2 | 8 | 8 | 8 | 8 | 4.2 | 4.2 | |

| 4.3 I | 5.1 | 4.3 | 4.3 | 6.1 | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 | ||

| 4.3 II | 5.1 | 4.3 | 4.3 | 6.1 | 4.3 | 4.3 | 4.3 | 8 | 8 | 4.3 | 4.3 | 4.3 | 4.3 | ||

| 4.3 III | 5.1 | 5.1 | 4.3 | 6.1 | 6.1 | 6.1 | 4.3 | 8 | 8 | 8 | 8 | 4.3 | 4.3 | ||

| 5.1 I1 | 5.1 | 5.1 | 5.1 | 5.1 | 5.1 | 5.1 | 5.1 | 5.1 | 5.1 | 5.1 | |||||

| 5.1 II1 | 6.1 | 5.1 | 5.1 | 5.1 | 8 | 8 | 5.1 | 5.1 | 5.1 | 5.1 | |||||

| 5.1 III1 | 6.1 | 6.1 | 6.1 | 5.1 | 8 | 8 | 8 | 8 | 5.1 | 5.1 | |||||

| 6.1 I, Dermal | 8 | 6.1 | 6.1 | 6.1 | 6.1 | 6.1 | |||||||||

| 6.1 I, Oral | 8 | 6.1 | 6.1 | 6.1 | 6.1 | 6.1 | |||||||||

| 6.1 II, Inhalation | 8 | 6.1 | 6.1 | 6.1 | 6.1 | 6.1 | |||||||||

| 6.1 II, Dermal | 8 | 6.1 | 8 | 6.1 | 6.1 | 6.1 | |||||||||

| 6.1 II, Oral | 8 | 8 | 8 | 6.1 | 6.1 | 6.1 | |||||||||

| 6.1 III | 8 | 8 | 8 | 8 | 8 | 8 |

The most stringent packing group assigned to a hazard of the material takes precedence over other packing groups; for example, a material meeting Class 3 PG II and Division 6.1 PG I (oral toxicity) is classified as Class 3 PG I.

A material which meets the definition of Class 8 and has an inhalation toxicity by dusts and mists which meets criteria for Packing Group I specified in § 173.133(a)(1) must be classed as Division 6.1 if the oral or dermal toxicity meets criteria for Packing Group I or II. If the oral or dermal toxicity meets criteria for Packing Group III or less, the material must be classed as Class 8.

(c) The following materials are not subject to the provisions of paragraph (a) of this section because of their unique properties:

(1) A Class 1 (explosive) material that meets any other hazard class or division as defined in this part shall be assigned a division in Class 1. Class 1 materials shall be classed and approved in accordance with § 173.56 of this part;

(2) A Division 5.2 (organic peroxide) material that meets the definition of any other hazard class or division as defined in this part, shall be classed as Division 5.2;

(3) A Division 6.2 (infectious substance) material that also meets the definition of another hazard class or division, other than Class 7, or that also is a limited quantity Class 7 material, shall be classed as Division 6.2;

(4) A material that meets the definition of a wetted explosive in § 173.124(a)(1) of this subchapter (Division 4.1). Wetted explosives are either specifically listed in the § 172.101 table or are approved by the Associate Administrator (see § 173.124(a)(1) of this subchapter); and

(5) A limited quantity of a Class 7 (radioactive) material that meets the definition for more than one hazard class or division shall be classed in accordance with § 173.423.

[Amdt. 173-224, 55 FR 52606, Dec. 21, 1990, as amended at 56 FR 66264, Dec. 20, 1991; Amdt. 173-241, 59 FR 67490, Dec. 29, 1994; Amdt. 173-247, 60 FR 48787, Sept. 20, 1995; Amdt. 173-244, 60 FR 50307, Sept. 28, 1995; 64 FR 10776, Mar. 5, 1999; 66 FR 33426, June 21, 2001; 66 FR 45182, 45379, Aug. 28, 2001; 68 FR 45032, July 31, 2003; 80 FR 1151, Jan. 8, 2015; 85 FR 27878, May 11, 2020]

§ 173.3 Packaging and exceptions.

(a) The packaging of hazardous materials for transportation by air, highway, rail, or water must be as specified in this part. Methods of manufacture, packing, and storage of hazardous materials, that affect safety in transportation, must be open to inspection by a duly authorized representative of the initial carrier or of the Department. Methods of manufacture and related functions necessary for completion of a DOT specification or U.N. standard packaging must be open to inspection by a representative of the Department.

(b) The regulations setting forth packaging requirements for a specific material apply to all modes of transportation unless otherwise stated, or unless exceptions from packaging requirements are authorized.

(c) Salvage drums. Packages of hazardous materials that are damaged, defective, or leaking; packages found to be not conforming to the requirements of this subchapter after having been placed in transportation; and, hazardous materials that have spilled or leaked may be placed in a metal or plastic removable head salvage drum that is compatible with the lading and shipped for repackaging or disposal under the following conditions:

(1) Except as provided in paragraph (c)(7) of this section, the drum must be a UN 1A2, 1B2, 1N2 or 1H2 tested and marked for Packing Group III or higher performance standards for liquids or solids and a leakproofness test of 20 kPa (3 psig). Alternatively, a drum manufactured and marked prior to October 1, 1993 as a salvage drum, in accordance with the provisions of this section in effect on September 30, 1991, is authorized. Capacity of the drum may not exceed 450 L (119 gallons).

(2) Each drum shall be provided when necessary with sufficient cushioning and absorption material to prevent excessive shifting of the damaged package and to eliminate the presence of any free liquid at the time the salvage drum is closed. All cushioning and absorbent material used in the drum must be compatible with the hazardous material.

(3) Each salvage packaging must be marked with the proper shipping name of the hazardous material inside the packaging and the name and address of the consignee. In addition, the packaging must be marked “SALVAGE”. The lettering of the marking must be at least 12 mm (0.5 inches) high.

(i) Transitional exception. A marking in conformance with the requirements of this paragraph in effect on December 31, 2014, may continue to be used until December 31, 2016.

(ii) For domestic transportation, a packaging marked prior to January 1, 2017 and in conformance with the requirements of this paragraph in effect on December 31, 2014, may continue in service until the end of its useful life.

(4) Each drum shall be labeled as prescribed for the respective material.

(5) The shipper shall prepare shipping papers in accordance with subpart C of part 172 of this subchapter.

(6) The overpack requirements of § 173.25 do not apply to drums used in accordance with this paragraph.

(7) A salvage packaging marked “T” in accordance with applicable provisions in the UN Recommendations may be used.

(d) Salvage cylinders. Cylinders of hazardous materials that are damaged or leaking may be overpacked in a non-DOT specification full opening hinged head or fully removable head steel salvage cylinder under the following conditions:

(1) Except for Class 1, Division 6.2, Class 7, or acetylene material, a cylinder containing a hazardous material may be overpacked in a salvage cylinder.

(2) Each salvage cylinder—

(i) Must be designed, constructed and marked in accordance with Section VIII, Division I of the ASME Code (IBR, see § 171.7 of this subchapter) with a minimum design margin of 4 to 1. Salvage cylinders may not be equipped with a pressure relief device. Damaged cylinders must be securely positioned in the salvage cylinder to prevent excessive shifting. The overpack requirements of § 173.25 do not apply to salvage cylinders used in accordance with this section.

(ii) Must have a maximum water capacity of 450 L (119 gallons).

(iii) Except for liquefied nitrous oxide and carbon dioxide, contents of the damaged or leaking cylinder must be limited in pressure and volume so that if totally discharged into the salvage cylinder, the pressure in the salvage cylinder will not exceed 5⁄4 of the MAWP at 55 °C (131 °F).

(iv) Must have gaskets, valves and fittings that are compatible with the hazardous materials contained within.

(3) Each salvage cylinder must be plainly and durably marked. Unless otherwise specified, the markings below must be in the same area on any portion of the upper end:

(i) The proper shipping name of the hazardous material contained inside the packaging;

(ii) The name and address of the consignee or consignor;

(iii) The name and address or registered symbol of the manufacturer; and

(iv) The word “SALVAGE” in letters at least 12 mm (0.5 inches) high on opposite sides near the middle of the cylinder; stamping on the sidewall is not authorized.

(A) Transitional exception. A marking in conformance with the requirements of this paragraph in effect on December 31, 2014, may continue to be used until December 31, 2016.

(B) For domestic transportation, a packaging marked prior to January 1, 2017 and in conformance with the requirements of this paragraph in effect on December 31, 2014, may continue in service until the end of its useful life.

(4) Each salvage cylinder must be labeled for the hazardous material contained inside the packaging.

(5) The shipper must prepare shipping papers in accordance with subpart C of part 172 of this subchapter.

(6) Transportation is authorized by motor vehicle and cargo vessel only.

(7) Each salvage cylinder must be cleaned and purged after each use.

(8) In addition to the training requirements of §§ 172.700 through 172.704 of this subchapter, a person who loads, unloads or transports a salvage cylinder must be trained in handling, loading and unloading the salvage cylinder.

(9) Cylinder Requalification: At least once every five years, each cylinder must be visually inspected (internally and externally) in accordance with CGA Pamphlet C-6 (IBR, see § 171.7 of this subchapter) and pressure tested. A minimum test pressure of at least 11⁄2 times MAWP must be maintained for at least 30 seconds. The cylinder must be examined under test pressure and removed from service if a leak or a defect is found.

(i) The retest and inspection must be performed by a person familiar with salvage cylinders and trained and experienced in the use of the inspection and testing equipment.

(ii) Each salvage cylinder that is successfully requalified must be durably and legibly marked with the word “Tested” followed by the requalification date (month/year), e.g., “Tested 9/04.” The marking must be in letters and numbers at least 12 mm (0.5 inches) high. The requalification marking may be placed on any portion of the upper end of the cylinder near the marking required in (d)(3) of this section or on a metal plate permanently secured to the cylinder. Stamping on the cylinder sidewall is not authorized.

(10) Record retention: The owner of each salvage cylinder or his authorized agent shall retain a record of the most recent visual inspection and pressure test until the salvage cylinder is requalified. The records must be made available to a DOT representative upon request.

(e) Emergency transportation of DOT 3A480 or 3AA480 cylinders and DOT 106A500 multi-unit tank car tanks.

(1) A DOT 3A480 or DOT 3AA480 cylinder containing chlorine or sulphur dioxide that has developed a leak in a valve or fusible plug may be repaired temporarily by trained personnel using a Chlorine Institute Kit “A” (with the exception of repair method using Device 8 for side leaks) (IBR, see § 171.7 of this subchapter). The repaired cylinder is authorized to be transported by private or contract carrier one time, one way, from the point of discovery to a proper facility for discharge and examination.

(2) A DOT 106A500 multi-unit tank car tank containing chlorine or sulphur dioxide that has developed a leak in the valve or fusible plug may be temporarily repaired by trained personnel using a Chlorine Institute Kit “B” (with the exception of repair method using Device 9 for side leaks) (IBR, see § 171.7 of this subchapter). The repaired tank is authorized to be transported by private or contract carrier one time, one way, from the point of discovery to a proper facility for discharge and examination.

(3) Training for personnel making the repairs in paragraphs (d)(1) and (d)(2) of this section must include:

(i) Proper use of the devices and tools in the applicable kits;

(ii) Use of respiratory equipment and all other safety equipment; and

(iii) Knowledge of the properties of chlorine and sulphur dioxide.

(4) Packagings repaired with “A” or “B” kits must be properly blocked and braced to ensure the packagings are secured in the transport vehicle.

(f) Large salvage packagings. Except for transportation by air, packages of hazardous materials that are damaged, defective, or leaking; packages found to be not conforming to the requirements of this subchapter after having been placed in transportation; and, hazardous materials that have spilled or leaked may be placed in a large salvage packaging that is compatible with the lading and shipped for repackaging or disposal under the following conditions:

(1) Large salvage packagings must be tested and marked in accordance with part 178, subparts P and Q of this subchapter at the Packing Group II or higher performance standards for large packagings intended for the transport of solids or inner packagings, except as follows:

(i) The test substance used in performing the tests shall be water, and the large salvage packagings must be filled to not less than 98 percent of their maximum capacity; and

(ii) Large salvage packagings must have been successfully subjected to a leakproofness test of 30 kPa (4.4 psig).

(2) Each large salvage packaging shall be provided when necessary with sufficient cushioning and absorption material to prevent excessive shifting of the contents and to eliminate the presence of any free liquid at the time the packaging is closed. All cushioning and absorbent material used in the large salvage packaging must be compatible with the hazardous material.

(3) Each large salvage packaging must be marked with the proper shipping name of the hazardous material inside the packaging and the name and address of the consignee. In addition, the packaging must be marked “SALVAGE”. The lettering of the marking must be at least 12 mm (0.5 inches) high.

(4) Each large salvage packaging shall be labeled as prescribed for the respective material.

(5) The shipper shall prepare shipping papers in accordance with subpart C of part 172 of this subchapter.

(6) The overpack requirements of § 173.25 do not apply to large salvage packagings used in accordance with this paragraph.

[Amdt. 173-224, 55 FR 52607, Dec. 21, 1990]

§ 173.4 Small quantities for highway and rail.

(a) When transported domestically by highway or rail in conformance with this section, quantities of Division 2.2 (except aerosols with no subsidiary hazard), Class 3, Division 4.1, Division 4.2 (PG II and III), Division 4.3 (PG II and III), Division 5.1, Division 5.2, Division 6.1, Class 7, Class 8, and Class 9 materials are not subject to any other requirements when—

(1) The maximum quantity of material per inner receptacle or article is limited to—

(i) Thirty (30) mL (1 ounce) for authorized liquids, other than Division 6.1, Packing Group I, Hazard Zone A or B materials;

(ii) Thirty (30) g (1 ounce) for authorized solid materials;

(iii) One (1) g (0.04 ounce) for authorized materials meeting the definition of a Division 6.1, Packing Group I, Hazard Zone A or B material; and

(iv) [Reserved]

(v) Thirty (30) mL water capacity (1.8 cubic inches) for authorized Division 2.2 materials.

(2) With the exception of temperature sensing devices, each inner receptacle:

(i) Is not liquid-full at 55 °C (131 °F), and

(ii) Is constructed of plastic having a minimum thickness of no less than 0.2 mm (0.008 inch), or earthenware, glass, or metal;

(3) Each inner receptacle with a removable closure has its closure held securely in place with wire, tape, or other positive means;

(4) Unless equivalent cushioning and absorbent material surrounds the inside packaging, each inner receptacle is securely packed in an inside packaging with cushioning and absorbent material that:

(i) Will not react chemically with the material, and

(ii) Is capable of absorbing the entire contents (if a liquid) of the receptacle;

(5) The inside packaging is securely packed in a strong outer packaging;

(6) The completed package, as demonstrated by prototype testing, is capable of sustaining—

(i) Each of the following free drops made from a height of 1.8 m (5.9 feet) directly onto a solid unyielding surface without breakage or leakage from any inner receptacle and without a substantial reduction in the effectiveness of the package:

(A) One drop flat on bottom;

(B) One drop flat on top;

(C) One drop flat on the long side;

(D) One drop flat on the short side; and

(E) One drop on a corner at the junction of three intersecting edges; and

(ii) A compressive load as specified in § 178.606(c) of this subchapter.

Each of the tests in paragraph (a)(6) of this section may be performed on a different but identical package; i.e., all tests need not be performed on the same package.

(7) Placement of the material in the package or packing different materials in the package does not result in a violation of § 173.21;

(8) The gross mass of the completed package does not exceed 29 kg (64 pounds);

(9) The package is not opened or otherwise altered until it is no longer in commerce; and

(10) The shipper certifies conformance with this section by marking the outside of the package with the statement “This package conforms to 49 CFR 173.4 for domestic highway or rail transport only.”

(b) A package containing a Class 7 (radioactive) material also must conform to the requirements of § 173.421(a) through (e), § 173.424(a) through (g), or § 173.426(a) through (c) as applicable.

(c) Packages which contain a Class 2 (other than those authorized in paragraph (a) of this section), Division 4.2 (PG I), or Division 4.3 (PG I) material conforming to paragraphs (a)(1) through (10) of this section may be offered for transportation or transported if approved by the Associate Administrator.

(d) Lithium batteries and cells are not eligible for the exceptions provided in this section.

[74 FR 2253, Jan. 14, 2009, as amended at 75 FR 5393, Feb. 2, 2010; 76 FR 3368, Jan. 19, 2011; 79 FR 40610, July 11, 2014; 80 FR 72924, Nov. 23, 2015]

§ 173.4a Excepted quantities.

(a) Excepted quantities of materials, other than articles (e.g., aerosols), are not subject to requirements of this subchapter except for:

(1) The shipper's responsibilities to properly class their material in accordance with § 173.22 of this subchapter;

(2) Sections 171.15 and 171.16 of this subchapter pertaining to the reporting of incidents; and

(3) For a Class 7 (Radioactive) material the requirements for an excepted package.

(4) Packagings for which retention of liquid is a basic function must be capable of withstanding without leakage the pressure differential specified in § 173.27(c) of this part.

(b) Authorized materials. Only materials authorized for transport aboard passenger aircraft and appropriately classed within one of the following hazard classes or divisions may be transported in accordance with this section:

(1) Division 2.2 material with no subsidiary hazard. An aerosol is not included as authorized Division 2.2 material;

(2) Class 3 materials;

(3) Class 4 (PG II and III) materials except for self-reactive materials;

(4) Division 5.1 (PG II and III);

(5) Division 5.2 materials only when contained in a chemical kit, first aid kit or a polyester resin kit;

(6) Division 6.1, other than PG I, Hazard Zone A or B material;

(7) Class 7, Radioactive material in excepted packages

(8) Class 8 (PG II and III), except for UN2803 (Gallium) and UN2809 (Mercury); and

(9) Class 9, except for UN1845 (Carbon dioxide, solid or Dry ice), and lithium batteries and cells.

(c) Inner packaging limits. The maximum quantity of hazardous materials in each inner packaging is limited to:

(1) For toxic material with a Division 6.1 primary or subsidiary hazard, PG I or II -

(i) 1 g (0.04 ounce) for solids; or

(ii) 1 mL (0.03 ounce) for liquids;

(2) 30 g (1 ounce) or 30 mL (1 ounce) for solids or liquids other than those covered in paragraph (c)(1) of this section; and

(3) For gases a water capacity of 30 mL (1.8 cubic inches) or less.

(d) Outer packaging aggregate quantity limits. The maximum aggregate quantity of hazardous material contained in each outer packaging must not exceed the limits provided in the following paragraphs. For outer packagings containing more than one hazardous material, the aggregate quantity of hazardous material must not exceed the lowest permitted maximum aggregate quantity. The limits are as follows:

(1) For other than a Division 2.2 or Division 5.2 material:

(i) Packing Group I - 300 g (0.66 pounds) for solids or 300 mL (0.08 gallons) for liquids;

(ii) Packing Group II - 500 g (1.1 pounds) for solids or 500 mL (0.1 gallons) for liquids;

(iii) Packing Group III - 1 kg (2.2 pounds) for solids or 1 L (0.2 gallons) for liquids;

(2) For Division 2.2 material, 1 L (61 cubic inches); or

(3) For Division 5.2 material, 500 g (1.1 pounds) for solids or 500 mL (0.1 gallons) for liquids.

(e) Packaging materials. Packagings used for the transport of excepted quantities must meet the following:

(1) Each inner receptacle must be constructed of plastic, or of glass, porcelain, stoneware, earthenware or metal. When used for liquid hazardous materials, plastic inner packagings must have a thickness of not less than 0.2 mm (0.008 inch).

(2) Each inner packaging with a removable closure must have its closure held securely in place with wire, tape or other positive means. Each inner receptacle having a neck with molded screw threads must have a leak proof, threaded type cap. The closure must not react chemically with the material.

(3) Each inner packaging must be securely packed in an intermediate packaging with cushioning material in such a way that, under normal conditions of transport, it cannot break, be punctured or leak its contents. The completed package as prepared for transport must completely contain the contents in case of breakage or leakage, regardless of package orientation. For liquid hazardous materials, the intermediate or outer packaging must contain sufficient absorbent material that:

(i) Will absorb the entire contents of the inner packaging.

(ii) Will not react dangerously with the material or reduce the integrity or function of the packaging materials.

(iii) When placed in the intermediate packaging, the absorbent material may be the cushioning material.

(4) The intermediate packaging must be securely packed in a strong, rigid outer packaging.

(5) Placement of the material in the package or packing different materials in the package must not result in a violation of § 173.21.

(6) Each package must be of such a size that there is adequate space to apply all necessary markings.

(7) The package is not opened or otherwise altered until it is no longer in commerce.

(8) Overpacks may be used and may also contain packages of hazardous material or other materials not subject to the HMR subject to the requirements of § 173.25.

(f) Package tests. The completed package as prepared for transport, with inner packagings filled to not less than 95% of their capacity for solids or 98% for liquids, must be capable of withstanding, as demonstrated by testing which is appropriately documented, without breakage or leakage of any inner packaging and without significant reduction in effectiveness:

(1) Drops onto a solid unyielding surface from a height of 1.8 m (5.9 feet):

(i) Where the sample is in the shape of a box, it must be dropped in each of the following orientations:

(A) One drop flat on the bottom;

(B) One drop flat on the top;

(C) One drop flat on the longest side;

(D) One drop flat on the shortest side; and

(E) One drop on a corner at the junction of three intersecting edges.

(ii) Where the sample is in the shape of a drum, it must be dropped in each of the following orientations:

(A) One drop diagonally on the top chime, with the center of gravity directly above the point of impact;

(B) One drop diagonally on the base chime; and

(C) One drop flat on the side.

(2) A compressive load as specified in § 178.606(c) of this subchapter. Each of the tests in this paragraph (f) of this section may be performed on a different but identical package; that is, all tests need not be performed on the same package.

(g) Marking. Excepted quantities of hazardous materials packaged, marked, and otherwise offered and transported in accordance with this section must be durably and legibly marked with the following marking:

(1) The “*” must be replaced by the primary hazard class, or when assigned, the division of each of the hazardous materials contained in the package. The “**” must be replaced by the name of the shipper or consignee if not shown elsewhere on the package.

(2) The marking must be durable and clearly visible and in the form of a square. The hatching must be of the same color, black or red on white or a suitable contrasting background. The minimum dimensions must not be less than 100 mm (3.9 inches) by 100 mm (3.9 inches) as measured from the outside of the hatching forming the border. Where dimensions are not specified, all features shall be in approximate proportion to those shown.

(i) Transitional exception - A marking in conformance with the requirements of this paragraph in effect on December 31, 2014, may continue to be used until December 31, 2016.

(ii) For domestic transportation, a packaging marked prior to January 1, 2017 and in conformance with the requirements of this paragraph in effect on December 31, 2014, may continue in service until the end of its useful life.

(3) When packages of excepted quantities are contained in an overpack, and the package marking required by this section is not visible inside the overpack, the excepted quantities marking must also be placed on the overpack. Additionally, an overpack containing packages of excepted quantities is not required to be marked with the word “OVERPACK.”

(h) Documentation.

(1) For transportation by highway or rail, no shipping paper is required.

(2) For transport by air, a shipping paper is not required, except that, if a document such as an air waybill accompanies a shipment, the document must include the statement “Dangerous Goods in Excepted Quantities” and indicate the number of packages.

(3) For transport by vessel, a shipping paper is required and must include the statement “Dangerous Goods in Excepted Quantities” and indicate the number of packages.

(i) Training. Each person who offers or transports excepted quantities of hazardous materials must know about the requirements of this section.

(j) Restrictions. Hazardous material packaged in accordance with this section may not be carried in checked or carry-on baggage.

[74 FR 2254, Jan. 14, 2009, as amended at 75 FR 72, Jan. 4, 2010; 76 FR 3368, Jan. 19, 2011; 80 FR 1152, Jan. 8, 2015; 81 FR 35541, June 2, 2016; 82 FR 15874, Mar. 30, 2017]

§ 173.4b De minimis exceptions.

(a) Packing Group II and III materials in Class 3, Division 4.1, Division 4.2, Division 4.3, Division 5.1, Division 6.1, Class 8, and Class 9 do not meet the definition of a hazardous material in § 171.8 of this subchapter when packaged in accordance with this section and, therefore, are not subject to the requirements of this subchapter.

(1) The maximum quantity of material per inner receptacle or article is limited to—

(i) One (1) mL (0.03 ounce) for authorized liquids; and

(ii) One (1) g (0.04 ounce) for authorized solid materials;

(2) Each inner receptacle with a removable closure has its closure held securely in place with wire, tape, or other positive means;

(3) Unless equivalent cushioning and absorbent material surrounds the inside packaging, each inner receptacle is securely packed in an inside packaging with cushioning and absorbent material that:

(i) Will not react chemically with the material, and

(ii) Is capable of absorbing the entire contents (if a liquid) of the receptacle;

(4) The inside packaging is securely packed in a strong outer packaging;

(5) The completed package is capable of sustaining—

(i) Each of the following free drops made from a height of 1.8 m (5.9 feet) directly onto a solid unyielding surface without breakage or leakage from any inner receptacle and without a substantial reduction in the effectiveness of the package:

(A) One drop flat on bottom;

(B) One drop flat on top;

(C) One drop flat on the long side;

(D) One drop flat on the short side; and

(E) One drop on a corner at the junction of three intersecting edges; and

(ii) A compressive load as specified in § 178.606(c) of this subchapter. Each of the tests in this paragraph (a)(5) may be performed on a different but identical package; that is, all tests need not be performed on the same package.

(6) Placement of the material in the package or packing different materials in the package does not result in a violation of § 173.21;

(7) The aggregate quantity of hazardous material per package does not exceed 100 g (0.22 pounds) for solids or 100 mL (3.38 ounces) for liquids;

(8) The gross mass of the completed package does not exceed 29 kg (64 pounds);

(9) The package is not opened or otherwise altered until it is no longer in commerce; and

(10) For transportation by aircraft:

(i) The hazardous material is authorized to be carried aboard passenger-carrying aircraft in Column 9A of the § 172.101 Hazardous Materials Table; and

(ii) Material packed in accordance with this section may not be carried in checked or carry-on baggage.

(b) Non-infectious specimens, such as specimens of mammals, birds, amphibians, reptiles, fish, insects and other invertebrates containing small quantities of Ethanol (UN1170), Formaldehyde solution, flammable (UN1198), Alcohols, n.o.s. (UN1987) and Isopropanol (UN1219) are not subject to the requirements of this subchapter provided the following packaging, marking and documentation provisions, as applicable, are met:

(1) The specimens are:

(i) Wrapped in a paper towel or cheesecloth moistened with alcohol or an alcohol solution and placed in a plastic bag that is heat-sealed. Any free liquid in the bag must not exceed 30 mL; or

(ii) Placed in vials or other rigid containers with no more than 30 mL of alcohol or alcohol solution. The containers are placed in a plastic bag that is heat-sealed;

(2) The bagged specimens are placed in another plastic bag with sufficient absorbent material to absorb the entire liquid contents inside the primary receptacle. The outer plastic bag is then heat-sealed;

(3) The completed bag is placed in a strong outer packaging with sufficient cushioning material that conforms to subpart B of part 173;

(4) The aggregate net quantity of flammable liquid in one outer packaging may not exceed 1 L; and

(5) The outer package must be legibly marked “Scientific research specimens, 49 CFR 173.4b applies.”

(6) Documentation.

(i) For transportation by highway or rail, no shipping paper is required.

(ii) For transport by air, a shipping paper is not required, except that, if a document such as an air waybill accompanies a shipment of specimens containing hazardous materials excepted under the terms of this section, the document must include the statement “Scientific research specimens, 49 CFR 173.4b applies” and the number of packages indicated.

(iii) For transport by vessel, a shipping paper is not required; however, the Dangerous Cargo Manifest must include the statement “Scientific research specimens, 49 CFR 173.4b applies” and the number of packages indicated. Vessel stowage is the same as for hazardous materials in excepted quantities.

(7) Training. Each person who offers or transports excepted quantities of hazardous materials must know about the requirements of this section.

(8) Restrictions. Except as provided in § 175.10, for transportation by aircraft, hazardous material packaged in accordance with this section may not be carried in checked or carry-on baggage by a passenger or crew member.

[74 FR 2255, Jan. 14, 2009, as amended at 75 FR 5393, Feb. 2, 2010; 76 FR 3368, Jan. 19, 2011; 78 FR 1073, Jan. 7, 2013]

§ 173.5 Agricultural operations.

(a) For other than a Class 2 material, the transportation of an agricultural product over local roads between fields of the same farm is excepted from the requirements of this subchapter. A Class 2 material transported over local roads between fields of the same farm is excepted from subparts G and H of part 172 of this subchapter. In either instance, transportation of the hazardous material is subject to the following conditions:

(1) It is transported by a farmer who is an intrastate private motor carrier; and

(2) The movement of the agricultural product conforms to requirements of the State in which it is transported and is specifically authorized by a State statute or regulation in effect before October 1, 1998.

(b) The transportation of an agricultural product to or from a farm, within 150 miles of the farm, is excepted from the requirements in subparts G and H of part 172 of this subchapter and from the specific packaging requirements of this subchapter when:

(1) It is transported by a farmer who is an intrastate private motor carrier;

(2) The total amount of agricultural product being transported on a single motor vehicle does not exceed:

(i) 7,300 kg (16,094 lbs.) of ammonium nitrate fertilizer properly classed as Division 5.1, PG III, in a bulk packaging, or

(ii) 1900 L (502 gallons) for liquids or gases, or 2,300 kg (5,070 lbs.) for solids, of any other agricultural product;

(3) The movement and packaging of the agricultural product conform to the requirements of the State in which it is transported and are specifically authorized by a State statute or regulation in effect before October 1, 1998; and

(4) Each person having any responsibility for transporting the agricultural product or preparing the agricultural product for shipment has been instructed in the applicable requirements of this subchapter.

(c) Formulated liquid agricultural products in specification packagings of 220 L (58 gallons) capacity, or less, with closures manifolded to a closed mixing system and equipped with positive dry disconnect devices may be transported by a private motor carrier between a final distribution point and an ultimate point of application or for loading aboard an airplane for aerial application.

(d) Moveable fuel storage tenders. A non-DOT specification cargo tank motor vehicle may be used to transport Liquefied petroleum gas, UN1075, including Propane, UN1978, as moveable fuel storage tender used exclusively for agricultural purposes when operated by a private carrier under the following conditions:

(1) The cargo tank must have a minimum design pressure of 250 psig.

(2) The cargo tank must meet the requirements of the HMR in effect at the time of its manufacture and must be marked accordingly. For questions regarding these requirements, contact PHMSA by either:

(i) Telephone (800) 467-4922 or (202) 366-4488 (local); or

(ii) By electronic mail (e-mail) to: infocntr@dot.gov.

(3) The cargo tank must have a water capacity of 1,200 gallons or less.

(4) The cargo tank must conform to applicable requirements in National Fire Protection Association (NFPA) 58, Liquefied Petroleum Gas Code (IBR, see § 171.7 of this subchapter).

(5) The cargo tank must be securely mounted on a motor vehicle.

(6) The cargo tank must be filled in accordance with § 173.315(b) for liquefied petroleum gas.

(7) The cargo tank must be painted white, aluminum, or other light-reflecting color.

(8) Transportation of the filled moveable fuel storage tender is limited to movements over local roads between fields using the shortest practical distance.

(9) Transportation of the moveable fuel storage tender between its point of use and a liquefied petroleum gas distribution facility is authorized only if the cargo tank contains no more than five percent of its water capacity. A movable fuel storage tender may only be filled at the consumer's premises or point of use.

(e) Liquid soil pesticide fumigants. MC 306 and DOT 406 cargo tank motor vehicles and DOT 57 portable tanks may be used to transport liquid soil pesticide fumigants, Pesticides, liquid, toxic, flammable, n.o.s., flash point not less than 23 degrees C, 6.1, UN2903, PG II, exclusively for agricultural operations by a private motor carrier between a bulk loading facility and a farm (including between farms). However, transportation is not to exceed 150 miles between the loading facility and the farm, and not more than five days are permitted for intermediate stops for temporary storage. Additionally, transport is permitted only under the following conditions:

(1) Cargo tanks. MC 306 and DOT 406 cargo tank motor vehicles must:

(i) Meet qualification and maintenance requirements (including periodic testing and inspection) in accordance with subpart E of part 180 of this subchapter;

(ii) Conform to the pressure relief system requirements specified in § 173.243(b)(1);

(iii) For MC 306 cargo tanks, be equipped with stop-valves capable of being remotely closed by manual and mechanical means; and

(iv) For DOT 406 cargo tanks, conform to the bottom outlet requirements specified in § 173.243(b)(2).

(2) Portable tanks. DOT 57 portable tanks must—

(i) Be constructed of stainless steel; and

(ii) Meet qualification and maintenance requirements of subpart G of part 180 of this subchapter.

(f) See § 173.315(m) pertaining to nurse tanks of anhydrous ammonia.

(g) See § 173.6 pertaining to materials of trade.

(h) See § 172.800(b) pertaining to security plans.

[Amdt. 173-259, 62 FR 1215, Jan. 8, 1997, as amended by Amdt. 173-262, 62 FR 49566, Sept. 22, 1997; Amdt. 173-259, 63 FR 8142, Feb. 18, 1998; 65 FR 50460, Aug. 18, 2000; 70 FR 73165, Dec. 9, 2005; 73 FR 4717, Jan. 28, 2008; 76 FR 5491, Feb. 1, 2011]

§ 173.5a Oilfield service vehicles, mechanical displacement meter provers, and roadway striping vehicles exceptions.

(a) Oilfield service vehicles. Notwithstanding § 173.29 of this subchapter, a cargo tank motor vehicle used in oilfield servicing operations is not subject to the specification requirements of this subchapter provided—

(1) The cargo tank and equipment contains only residual amounts (i.e., it is emptied so far as practicable) of a flammable liquid alone or in combination with water,

(2) No flame producing device is operated during transportation, and

(3) The proper shipping name is preceded by “RESIDUE: LAST CONTAINED * * * ” on the shipping paper for each movement on a public highway.

(b) Mechanical displacement meter provers.

(1) A mechanical displacement meter prover, as defined in § 171.8 of this subchapter, permanently mounted on a truck chassis or trailer and transported by motor vehicle is excepted from the specification packaging requirements in part 178 of this subchapter provided it—

(i) Contains only the residue of a Division 2.1 (flammable gas) or Class 3 (flammable liquid) material. For liquids, the meter prover must be drained to not exceed 10% of its capacity or, to the extent that draining of the meter prover is impracticable, to the maximum extent practicable. For gases, the meter prover must not exceed 25% of the marked pressure rating;

(ii) Has a water capacity of 3,785 L (1,000 gallons) or less;

(iii) Is designed and constructed in accordance with chapters II, III, IV, V and VI of ASME Standard B31.4 (IBR, see § 171.7 of this subchapter);

(iv) Is marked with the MAWP determined from the pipe component with the lowest pressure rating; and

(v) Is equipped with rear-end protection as prescribed in § 178.337-10(c) of this subchapter and 49 CFR 393.86 of the Federal Motor Carrier Safety Regulations.

(2) The description on the shipping paper for a meter prover containing the residue of a hazardous material must include the phrase “RESIDUE: LAST CONTAINED * * * ” before the basic description.

(3) Periodic test and inspection.

(i) Each meter prover must be externally visually inspected once a year. The external visual inspection must include at a minimum: checking for leakage, defective fittings and welds, defective closures, significant dents and other defects or abnormalities which indicate a potential or actual weakness that could render the meter prover unsafe for transportation; and

(ii) Each meter prover must be pressure tested once every 5 years at not less than 75% of design pressure. The pressure must be held for a period of time sufficiently long to assure detection of leaks, but in no case less than 5 minutes.

(4) In addition to the training requirements in subpart H, the person who performs the visual inspection or pressure test and/or signs the inspection report must have the knowledge and ability to perform them as required by this section.

(5) A meter prover that fails the periodic test and inspection must be rejected and removed from hazardous materials service unless the meter prover is adequately repaired, and thereafter, a successful test is conducted in accordance with the requirements of this section.

(6) Prior to any repair work, the meter prover must be emptied of any hazardous material. A meter prover containing flammable lading must be purged.

(7) Each meter prover successfully completing the external visual inspection and the pressure test must be marked with the test date (month/year), and the type of test or inspection as follows:

(i) V for external visual inspection; and

(ii) P for pressure test.

The marking must be on the side of a tank or the largest piping component in letters 32 mm (1.25 inches) high on a contrasting background.

(8) The owner must retain a record of the most recent external visual inspection and pressure test until the next test or inspection of the same type is successfully completed. The test or inspection report must include the following:

(i) Serial number or other meter prover identifier;

(ii) Type of test or inspection performed;

(iii) Test date (month/year);

(iv) Location of defects found, if any, and method used to repair each defect;

(v) Name and address of person performing the test or inspection;

(vi) Disposition statement, such as “Meter Prover returned to service” or “Meter Prover removed from service”.

(c) Roadway striping. In addition to conformance with all other applicable requirements of this subchapter, non-DOT specification cargo tanks used for roadway striping are authorized provided all the following conditions in this paragraph (c) are met.

(1) Authorized materials. Only the hazardous materials listed in the table 1 to this paragraph (c)(1) may be transported in roadway striping vehicles. Cargo tanks may not be filled to a capacity that would be greater than liquid full at 130 °F.

Table 1 to Paragraph (c)(1)—Hazardous Materials Description

| Proper shipping name | Hazard class/

division |

Identification No. | Packing

group |

|---|---|---|---|

| Acetonea | 3 | UN1090 | II. |

| Adhesives, containing a flammable liquid | 3 | UN1133 | II. |

| Amines, liquid, corrosive, n.o.s.b or Polyamines, liquid, corrosive, n.o.sb | 8 | UN2735 | III. |

| Corrosive liquid, basic, organic, n.o.sb | 8 | UN3267 | III. |

| Corrosive liquids, n.o.sb | 8 | UN1760 | III. |

| Dichloromethanea | 6.1 | UN1593 | III. |

| Elevated temperature liquid, n.o.s., at or above 100 °C and below its flash point (including molten metals, molten salts, etc.)c | 9 | UN3257 | III. |

| Environmentally hazardous substance, liquid, n.o.sb | 9 | UN3082 | III. |

| Ethyl acetatea | 3 | UN1173 | II. |

| Ethyl methyl ketone or Methyl ethyl ketonea | 3 | UN1193 | II. |

| Flammable liquids, n.o.sd | 3 | UN1993 | II. |

| Gasoline | 3 | UN1203 | II. |

| Methanola | 3 | UN1230 | II. |

| Organic peroxide type E, liquid (Dibenzoyl peroxide)b | 5.2 | UN3107 | NA. |

| Paint including paint, lacquer, enamel, stain, shellac solution, varnish, polish, liquid filler, and liquid lacquer base | 3 | UN1263 | II. |

| Paint related material including paint thinning drying, removing, or reducing compound | 3 | UN1263 | II. |

| Petroleum distillates, n.o.s. or Petroleum products, n.o.sa | 3 | UN1268 | III. |

| Toluenea | 3 | UN1294 | II. |

| 1,1,1-Trichloroethanea | 6.1 | UN2831 | III. |

| Xylenesa | 3 | UN1307 | II, III. |

(2) Cargo tank requirements. Each non-DOT specification cargo tank used for roadway striping must be securely bolted to a motor vehicle and must—

(i) Be constructed and certified in conformance with the HMR in effect at the time of its manufacture and must be marked accordingly. For questions regarding these requirements, contact PHMSA by either: (1) Telephone (800) 467-4922 or (202) 366-4488 (local); or (2) by electronic mail (e-mail) to: infocntr@dot.gov;

(ii) Have a minimum design pressure of 100 psig;

(iii) Have a maximum capacity of 500 gallons;

(iv) For solvents and organic peroxides, the cargo tank may not contain more than 50 gallons;

(v) Be given an external visual inspection prior to each use to ensure that it has not been damaged on the previous trip;

(vi) Be retested and reinspected in accordance with § 180.407(c) of this subchapter as specified for an MC 331 cargo tank motor vehicle; and

(vii) Be securely mounted to a motor vehicle in accordance with the securement provisions prescribed in §§ 393.100 through 393.106 of this title.

(3) Test records. The owner or operator of the roadway striping vehicle must maintain hydrostatic test records in accordance with § 180.417(b) and must make those records available to any representative of the Department of Transportation upon request.

(4) Marking. A non-DOT specification cargo tank used for roadway striping must be plainly marked on both sides near the middle in letters at least two inches in height on a contrasting background “ROADWAY STRIPING”.

(5) Operational controls. A non-DOT specification cargo tank used for roadway striping may not be pressurized when the motor vehicle is traveling to and from job sites. Additionally, the distance traveled by a non-DOT specification cargo tank used for roadway striping may not exceed 750 miles. Thermoplastic resin may only be heated during roadway striping operations.

[70 FR 3308, Jan. 24, 2005, as amended at 75 FR 27213, May 14, 2010; 76 FR 5492, Feb. 1, 2011; 83 FR 55807, Nov. 7, 2018]

§ 173.5b Portable and mobile refrigeration systems.

This section authorizes the highway transportation of residual amounts of Division 2.2 refrigerant gases or anhydrous ammonia contained in non-specification pressure vessels that are components of refrigeration systems, which may or may not be permanently mounted to a transport vehicle, used for agricultural operations. These refrigeration systems are used at field sites to cool (pre-cool) produce before the produce is loaded into trucks or railcars for market or used to supplement stationary refrigeration systems during peak harvest times. The components of these refrigeration systems are commonly known as vacuum tubes, accumulators, refrigeration units, ice makers, pressure coolers, or evaporators.

(a) General packaging requirements. Each non-specification pressure vessel must conform to the following:

(1) Each pressure vessel must be designed, manufactured, and maintained in accordance with applicable requirements of the ASME Code (IBR, see § 171.7 of this subchapter).

(2) Except as authorized in this section, each pressure vessel and associated piping must be rated at a maximum allowable work pressure (MAWP) of 250 psig. The pressure in these components may not exceed MAWP.

(3) Any part of the piping or pressure vessel separated from another component of the refrigeration system by means of a valve, blank flange, or other device must be equipped with a pressure relief valve set at MAWP. All lines that must be disconnected for transportation purposes must be closed by means of a cap, plug or blank flange, and valves at the end of disconnected lines must be tightly closed.

(4) The aggregate total volumetric capacity of components within the refrigeration system authorized for highway transportation in accordance with this section may not exceed 2,500 gallons per vehicle.

(5) Each pressure vessel and associated piping containing anhydrous ammonia must conform to the following:

(i) Piping with a diameter of 2 inches or more must conform to ASTM A 53 Schedule 40 or ASTM A106 Schedule 40 (IBR, see § 171.7 of this subchapter).

(ii) Piping with a diameter of less than 2 inches must conform to ASTM A 53 Schedule 80 or ASTM A 106 Schedule 80 (IBR, see § 171.7 of this subchapter).

(iii) The words “Inhalation Hazard” must be marked as required in special provision 13 in § 172.102 of this subchapter and, when practicable, within 24 inches of the placard.

(b) Refrigeration systems placed into service prior to June 1, 1991.

(1) For refrigeration systems placed into service prior to June 1, 1991, each pressure vessel and associated piping must be rated at a MAWP of not less than 250 psig. During transportation, pressure in the components that are part of the evaporating line may not exceed 150 psig.

(2) Each pressure vessel and associated piping that is part of the evaporating line must be marked “LOW SIDE” in a permanent and clearly visible manner. The evaporating line must have a pressure gauge with corresponding temperature markings mounted in a manner that is easily readable when standing on the ground. The gauge must be permanently marked or tagged “SATURATION GAUGE.”

(3) Each pressure vessel and associated piping containing liquid anhydrous ammonia must be isolated using appropriate means from piping and components marked “LOW SIDE.”

(4) Prior to transportation, each pressure vessel and associated piping must be relieved of enough gaseous lading to ensure that the MAWP is not exceeded at transport temperatures up to 54 °C (130 °F).

(c) Prior to transportation over public highways, each pressure vessel and associated piping must be drained of refrigerant gas or liquid anhydrous ammonia to the extent practicable. Drained contents must be recovered in conformance with all applicable environmental regulations. Residual liquid anhydrous ammonia in each component may not exceed one percent of the component's total volumetric capacity or 10 gallons, whichever is less.

(d) System inspection and testing.

(1) Each refrigeration system authorized under this section must be visually inspected every year. The visual inspection must include items listed in § 180.407(d)(2) of this subchapter applicable to refrigeration systems. A certificate of the annual visual inspection must be dated and signed by the person performing the inspection and must contain that person's company affiliation. The certificate must remain at the equipment owner's office.

(2) Each refrigeration system authorized under this section must be proof pressure tested every two years beginning with the initial pressure test performed after manufacture. Additional pressure tests must be performed after any modification, repair or damage to a part of the system pressurized with refrigerant gas. System test pressures may not be less than one-and-one-half (1.50) times the rated MAWP of the system component or piping.

(3) Pressure relief valves must be successfully tested every two years at the MAWP for the components or piping to which they are attached. Pressure relief valves may be replaced and marked every 5 years with valves certified at the appropriate MAWP, in which case the valves need not be tested every two years. Valves that do not pass the test must be repaired or replaced.

(e) Test markings and reports.

(1) Evidence of testing specified in paragraph (d) of this section must be marked on the right forward side of the refrigeration system with 2 inch high letters indicating type of last test (V = visual; P = pressure: hydrostatic or pneumatic) and the month/year in which it was performed. Reports and all of the requirements for records of inspections including markings must be completed as specified in part 180.

(2) Pressure relief valves must be durably marked with either the date of last test, set-pressure and testing company or the date of last replacement, set-pressure, and certifying company, as applicable.

[74 FR 16142, Apr. 9, 2009, as amended at 85 FR 75712, Nov. 25, 2020]

§ 173.6 Materials of trade exceptions.

When transported by motor vehicle in conformance with this section, a material of trade (see § 171.8 of this subchapter) is not subject to any other requirements of this subchapter besides those set forth or referenced in this section.

(a) Materials and amounts. A material of trade is limited to the following:

(1) A Class 3, 8, 9, Division 4.1, 5.1, 5.2, 6.1, or ORM-D material contained in a packaging having a gross mass or capacity not over -

(i) 0.5 kg (1 pound) or 0.5 L (1 pint) for a Packing Group I material;

(ii) 30 kg (66 pounds) or 30 L (8 gallons) for a Packing Group II, Packing Group III, or ORM-D material;

(iii) 1500 L (400 gallons) for a diluted mixture, not to exceed 2 percent concentration, of a Class 9 material.

(2) A Division 2.1 or 2.2 material in a cylinder with a gross weight not over 100 kg (220 pounds), in a Dewar flask meeting the requirements of § 173.320, or a permanently mounted tank manufactured to the ASME Code of not more than 70 gallon water capacity for a non-liquefied Division 2.2 material with no subsidiary hazard.

(3) A Division 4.3 material in Packing Group II or III contained in a packaging having a gross capacity not exceeding 30 mL (1 ounce).

(4) A Division 6.2 material, other than a Category A infectious substance, contained in human or animal samples (including, but not limited to, secreta, excreta, blood and its components, tissue and tissue fluids, and body parts) being transported for research, diagnosis, investigational activities, or disease treatment or prevention, or is a biological product or regulated medical waste. The material must be contained in a combination packaging. For liquids, the inner packaging must be leakproof, and the outer packaging must contain sufficient absorbent material to absorb the entire contents of the inner packaging. For sharps, the inner packaging (sharps container) must be constructed of a rigid material resistant to punctures and securely closed to prevent leaks or punctures, and the outer packaging must be securely closed to prevent leaks or punctures. For solids, liquids, and sharps, the outer packaging must be a strong, tight packaging securely closed and secured against shifting, including relative motion between packages, within the vehicle on which it is being transported.

(i) For other than a regulated medical waste, the amount of Division 6.2 material in a combination packaging must conform to the following limitations:

(A) One or more inner packagings, each of which may not contain more than 0.5 kg (1.1 lbs) or 0.5 L (17 ounces), and an outer packaging containing not more than 4 kg (8.8 lbs) or 4 L (1 gallon); or

(B) A single inner packaging containing not more than 16 kg (35.2 lbs) or 16 L (4.2 gallons) in a single outer packaging.

(ii) For a regulated medical waste, a combination packaging must consist of one or more inner packagings, each of which may not contain more than 4 kg (8.8 lbs) or 4 L (1 gallon), and an outer packaging containing not more than 16 kg (35.2 lbs) or 16 L (4.2 gallons).

(5) This section does not apply to a hazardous material that is self-reactive (see § 173.124), poisonous by inhalation (see § 173.133), or a hazardous waste.

(6) A limited quantity package prepared in accordance with § 173.63(b), § 173.150, § 173.151(b) and (c), § 173.152, § 173.153, § 173.154, § 173.155, § 173.161, § 173.165, § 173.167, § 173.306(i), or § 173.309(d) of this subchapter. Division 4.3 substances must be prepared in accordance with paragraph (a)(3) of this section. Class 7 (radioactive) substances, instruments and articles are not authorized under the provisions of this section.

(7) For a material or article for which Column (5) of the Hazardous Materials Table in § 172.101 of this subchapter does not indicate a packing group. Authorized amounts are:

(i) For Classes or Divisions indicated in paragraph (a)(1) of this section, the amounts shown in paragraph (a)(1)(ii).

(ii) For Division 4.3, the amounts shown in paragraph (a)(3) of this section.

(b) Packaging.

(1) Packagings must be leak tight for liquids and gases, sift proof for solids, and be securely closed, secured against shifting, and protected against damage.

(2) Each material must be packaged in the manufacturer's original packaging, or a packaging of equal or greater strength and integrity.

(3) Outer packagings are not required for receptacles (e.g., cans and bottles) or articles that are secured against shifting in cages, carts, bins, boxes, or compartments or by other means.

(4) For gasoline, a packaging must be made of metal or plastic and conform to the requirements of this subchapter or to the requirements of the Occupational Safety and Health Administration of the Department of Labor contained in 29 CFR 1910.106(d)(2) or 1926.152(a)(1).

(5) A cylinder or other pressure vessel containing a Division 2.1 or 2.2 material must conform to packaging, qualification, maintenance, and use requirements of this subchapter, except that outer packagings are not required. Manifolding of cylinders is authorized provided all valves are tightly closed.

(c) Hazard communication.

(1) A non-bulk packaging other than a cylinder (including a receptacle transported without an outer packaging) must be marked with a common name or proper shipping name to identify the material it contains, including the letters “RQ” if it contains a reportable quantity of a hazardous substance.

(2) A bulk packaging containing a diluted mixture of a Class 9 material must be marked on two opposing sides with the four-digit identification number of the material. The identification number must be displayed on placards, orange panels or, alternatively, a white square-on-point configuration having the same outside dimensions as a placard (at least 273 mm (10.8 inches) on a side), in the manner specified in § 172.332 (b) and (c) of this subchapter.

(3) A DOT specification cylinder (except DOT specification 39) must be marked and labeled as prescribed in this subchapter. Each DOT-39 cylinder must display the markings specified in 178.65(i).

(4) The operator of a motor vehicle that contains a material of trade must be informed of the presence of the hazardous material (including whether the package contains a reportable quantity) and must be informed of the requirements of this section.

(d) Aggregate gross weight. Except for a material of trade authorized by paragraph (a)(1)(iii) of this section, the aggregate gross weight of all materials of trade on a motor vehicle may not exceed 200 kg (440 pounds).

(e) Other exceptions. A material of trade may be transported on a motor vehicle under the provisions of this section with other hazardous materials without affecting its eligibility for exceptions provided by this section.

[Amdt. 173-259, 62 FR 1216, Jan. 8, 1997, as amended by Amdt. 173-262, 62 FR 49566, Sept. 22, 1997; 62 FR 51560, Oct. 1, 1997; Amdt. 173-259, 63 FR 8142, Feb. 18, 1998; 63 FR 52849, Oct. 1, 1998; 66 FR 45381, Aug. 28, 2001; 67 FR 53137, Aug. 14, 2002; 68 FR 75742, Dec. 31, 2003; 68 FR 61941, Oct. 30, 2003; 71 FR 32258, June 2, 2006; 72 FR 55692, Oct. 1, 2007; 78 FR 1113, Jan. 7, 2013; 78 FR 15326, Mar. 11, 2013; 78 FR 65478, Oct. 31, 2013; 85 FR 27878, May 11, 2020]

§ 173.7 Government operations and materials.

(a) Hazardous materials offered for transportation by, for, or to the Department of Defense (DOD) of the U.S. Government, including commercial shipments pursuant to a DOD contract, must be packaged in accordance with the regulations in this subchapter or in packagings of equal or greater strength and efficiency as certified by DOD in accordance with the procedures prescribed by “Packaging of Hazardous Material, DLAR 4145.41/AR 700-143/NAVSUPINST 4030.55D/AFMAN 24-210__IP/MCO 4030.40C (IBR, see § 171.7 of this subchapter).” Hazardous materials offered for transportation by DOD under this provision may be reshipped by any shipper to any consignee provided the original packaging has not been damaged or altered in any manner.

(1) Hazardous materials sold by the DOD in packagings that are not marked in accordance with the requirements of this subchapter may be shipped from DOD installations if the DOD certifies in writing that the packagings are equal to or greater in strength and efficiency than the packaging prescribed in this subchapter. The shipper shall obtain such a certification in duplicate for each shipment. He shall give one copy to the originating carrier and retain the other for no less than 1 year.

(2) [Reserved]

(b) Shipments of hazardous materials, made by or under the direction or supervision of the U.S. Department of Energy (DOE) or the Department of Defense (DOD), for the purpose of national security, and which are escorted by personnel specifically designated by or under the authority of those agencies, are not subject to the requirements of this subchapter. For transportation by a motor vehicle or a rail car, the escorts must be in a separate transport vehicle from the transport vehicle carrying the hazardous materials that are excepted by this paragraph. A document certifying that the shipment is for the purpose of national security must be in the possession of the person in charge of providing security during transportation.

(c) Shipments of explosive samples, not exceeding 1 g net weight, offered by and consigned to the Bureau of Alcohol, Tobacco and Firearms (ATF) of the Department of the Treasury are not otherwise subject to the regulations in parts 110-189 of this subchapter when placed in a specifically designed multi-unit assembly packed in a strong outer packaging. The packaging must be of a type accepted by ATF as capable of precluding a propagation of any explosion outside the packaging. The second component from the outside of the packaging must be marked or tagged to indicate the presence of an explosive.

(d) Notwithstanding the requirements of §§ 173.416 and 173.417 of this subchapter, packagings made by or under the direction of the U.S. Department of Energy may be used for the transportation of Class 7 materials when evaluated, approved, and certified by the Department of Energy against packaging standards equivalent to those specified in 10 CFR part 71. Packages shipped in accordance with this paragraph shall be marked and otherwise prepared for shipment in a manner equivalent to that required by this subchapter for packagings approved by the Nuclear Regulatory Commission.

(e) Class 1 (explosive) materials owned by the Department of Defense and packaged prior to January 1, 1990, in accordance with the requirements of this subchapter in effect at that time, are excepted from the marking and labeling requirements of part 172 of this subchapter and the packaging and package marking requirements of part 178 of this subchapter, provided the packagings have maintained their integrity and the explosive material is declared as “government-owned goods packaged prior to January 1, 1990” on the shipping papers. In addition, packages of these materials owned by the Department of Defense that are marked and labeled in conformance with the requirements of the HMR that were in effect at the time they were originally marked and labeled are excepted from the current marking and labeling requirements.

(f) The requirements of this subchapter do not apply to shipments of hazardous materials carried aboard an aircraft that is not owned by a government or engaged in carrying persons or property for commercial purposes, but is under the exclusive direction and control of the government for a period of not less than 90 days as specified in a written contract or lease. An aircraft is under the exclusive direction and control of a government when the government exercises responsibility for:

(1) Approving crew members and determining they are qualified to operate the aircraft;

(2) Determining the airworthiness and directing maintenance of the aircraft; and

(3) Dispatching the aircraft, including the times of departure, airports to be used, and type and amount of cargo to be carried.

[29 FR 18671, Dec. 29, 1964. Redesignated at 32 FR 5606, Apr. 5, 1967]

§ 173.8 Exceptions for non-specification packagings used in intrastate transportation.

(a) [Reserved]

(b) Non-specification cargo tanks for petroleum products. Notwithstanding requirements for specification packagings in subpart F of this part and parts 178 and 180 of this subchapter, a non-specification cargo tank motor vehicle having a capacity of less than 13,250 L (3,500 gallons) may be used by an intrastate motor carrier for transportation of a flammable liquid petroleum product in accordance with the provisions of paragraph (d) of this section.

(c) Permanently secured non-bulk tanks for petroleum products. Notwithstanding requirements for specification packagings in subpart F of this part 173 and parts 178 and 180 of this subchapter, a non-specification metal tank permanently secured to a transport vehicle and protected against leakage or damage in the event of a turnover, having a capacity of less than 450 L (119 gallons), may be used by an intrastate motor carrier for transportation of a flammable liquid petroleum product in accordance with the provisions of paragraph (d) of this section.

(d) Additional requirements. A packaging used under the provisions of paragraphs (a), (b) or (c) of this section must—

(1) Be operated by an intrastate motor carrier and in use as a packaging for hazardous material before October 1, 1998;

(2) Be operated in conformance with the requirements of the State in which it is authorized;

(3) Be specifically authorized by a State statute or regulation in effect before October 1, 1998, for use as a packaging for the hazardous material being transported;

(4) Be offered for transportation and transported in conformance with all other applicable requirements of this subchapter;

(5) Not be used to transport a flammable cryogenic liquid, hazardous substance, hazardous waste, or a marine pollutant (except for gasoline); and

(6) For a tank authorized under paragraph (b) or (c) of this section, conform to all requirements in part 180 (except for § 180.405(g)) of this subchapter in the same manner as required for a DOT specification MC 306 cargo tank motor vehicle.

[Amdt. 173-259, 62 FR 1216, Jan. 8, 1997, as amended by Amdt. 172-262, 62 FR 49567, Sept. 22, 1997; Amdt. 173-259, 63 FR 8142, Feb. 18, 1998; 66 FR 45380, Aug. 28, 2001; 76 FR 56315, Sept. 13, 2011; 80 FR 72924, Nov. 23, 2015]

§ 173.9 Transport vehicles or freight containers containing lading which has been fumigated.

(a) For the purpose of this section, not including 49 CFR part 387, a rail car, freight container, truck body, or trailer in which the lading has been fumigated with any material, or is undergoing fumigation, is a package containing a hazardous material.

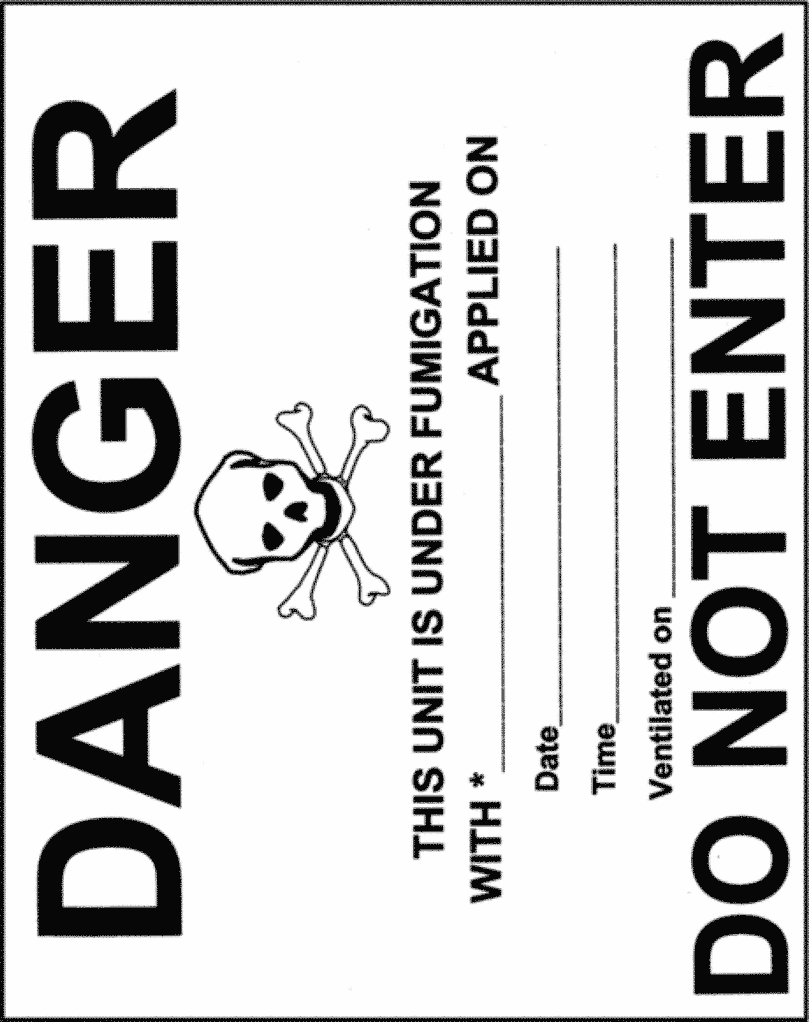

(b) No person may offer for transportation or transport a rail car, freight container, truck body, or trailer in which the lading has been fumigated or treated with any material, or is undergoing fumigation, unless the FUMIGANT marking specified in paragraph (e) of this section is prominently displayed so that it can be seen by any person attempting to enter the interior of the transport vehicle or freight container. For domestic transportation, a hazard warning label authorized by EPA under 40 CFR part 156 may be used as an alternative to the FUMIGANT marking.

(c) No person may affix or display on a rail car, freight container, truck body, or trailer the FUMIGANT marking specified in paragraph (e) of this section, unless the lading has been fumigated or is undergoing fumigation.

(d) The FUMIGANT marking required by paragraph (b) of this section must remain on the rail car, freight container, truck body, or trailer until the rail car, freight container, truck body, or trailer has been completely ventilated either by opening the doors of the unit or by mechanical ventilation to ensure no harmful concentration of gas remains after fumigation has been completed.

(e) FUMIGANT marking.

(1) The FUMIGANT marking must consist of black letters on a white background that is a rectangle at least 400 mm (15.75 inches) wide and at least 300 mm (11.8 inches) high as measured to the outside of the lines forming the border of the marking. The minimum width of the line forming the border must be 2 mm and the text on the marking must not be less than 25 mm high. Except for size and color, the FUMIGANT marking must be as shown in the following figure. Where dimensions are not specified, all features shall be in approximate proportion to those shown.

(i) The marking, and all required information, must be capable of withstanding, without deterioration or a substantial reduction in effectiveness, a 30-day exposure to open weather conditions.

(2) The “*” shall be replaced with the technical name of the fumigant.

(f) A closed cargo transport unit that has been fumigated is not subject to any other provisions of this subchapter if it—

(1) Has been completely ventilated either by opening the doors of the unit or by mechanical ventilation after fumigation, and

(2) Displays the FUMIGANT marking, including the date of ventilation.

(g) For international shipments, transport documents should indicate the date of fumigation, type and amount of fumigant used, and instructions for disposal of any residual fumigant, including fumigation devices.

(h) Any person subject to the requirements of this section, solely due to the fumigated lading, must be informed of the requirements of this section and the safety precautions necessary to protect themselves and others in the event of an incident or accident involving the fumigated lading.

(i) Any person who offers for transportation or transports a rail car, freight container, truck body or trailer that is subject to this subchapter solely because of the hazardous materials designation specified in paragraph (a) of this section is not subject to any requirements of this subchapter other than those contained in this section.

[71 FR 78629, Dec. 29, 2006, as amended at 80 FR 1152, Jan. 8, 2015; 82 FR 15874, Mar. 30, 2017]

§ 173.10 Tank car shipments.